Table of content

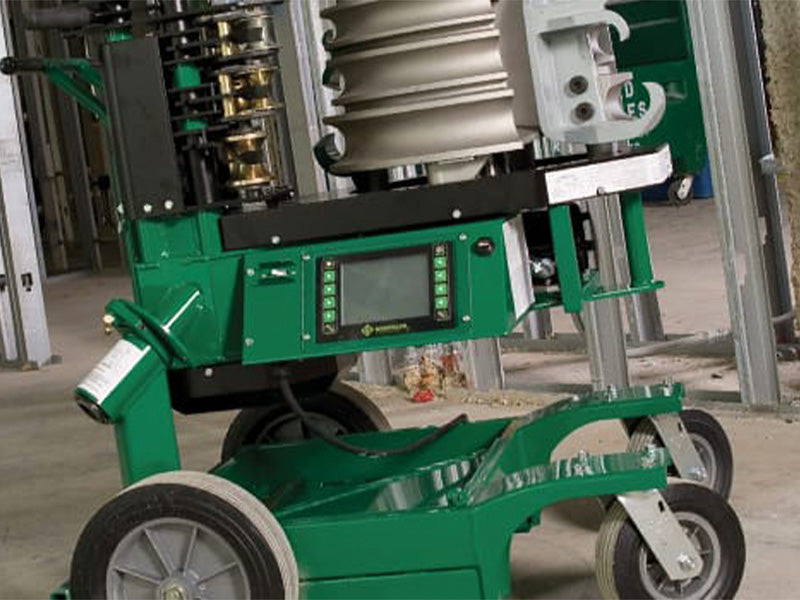

Greenlee 855GX: Revolutionizing Conduit Bending with Smart Technology

Are you tired of the time-consuming and labor-intensive conduit bending process? Do you face challenges with complex bends and the need for precise and repeatable results? The Greenlee 855GX Smart Bender is here to revolutionize your work and make conduit bending easy.

With its advanced technology and exceptional efficiency gains, the Greenlee 855GX is the ultimate solution for electricians and professionals seeking to streamline their bending operations. Eliminate the guesswork and tedious manual bending techniques. This smart bender offers programmable capabilities that take the guessing out of bending, allowing you to achieve accurate and consistent results every time.

Imagine the convenience of effortlessly switching between horizontal and vertical bending with just a few simple steps. Picture the time and effort saved when complex bends become effortless. The Greenlee 855GX empowers you to conquer these challenges easily, bringing simplicity and precision to your workflow.

The Greenlee 855GX’s user-friendly interface, robust construction, and versatile bending capabilities make it ideal for any conduit bending task.

Greenlee 855GX Smart Bender Technology: Bend 4x Faster

Efficiency gains are at the core of the Greenlee 855GX Smart Bender, and its advanced technology enables electricians to bend conduit four times faster than traditional manual methods.

The Greenlee 855GX has state-of-the-art technology streamlining the bending process and eliminating time-consuming manual adjustments. With its innovative design and intelligent features, this smart bender takes efficiency to new heights.

One of the key technological advancements of the Greenlee 855GX is its ability to accomplish any bend, including complex 3D bends, with unparalleled speed. The user-friendly LCD interface allows electricians to configure and execute bends precisely, saving time on every project. Whether bending rigid, EMT, or IMC conduit, the Greenlee 855GX delivers exceptional results in a fraction of the time.

Check out this detailed How-To video on the Greenlee 855GX IntelliBender

The benefits of increased productivity and time savings cannot be overstated. With the Greenlee 855GX Smart Bender, electricians can complete bending tasks in a fraction of the time it would take using traditional methods. This translates to more jobs completed, higher project throughput, and increased profitability.

Not only does the Greenlee 855GX improve efficiency, but it also reduces the physical strain on electricians. Automating the bending process eliminates the need for repetitive manual bending and minimizes fatigue and injury risk. Electricians can work more comfortably and confidently, knowing that the Greenlee 855GX is there to support them.

Programmable Bending: Automate Complex Bends

The Greenlee 855GX is equipped with a revolutionary programmable bending feature that takes bending operations to new heights of efficiency and accuracy. This advanced capability allows electricians to easily automate complex bends, reducing human error and improving overall precision.

The programmable bending feature of the Greenlee 855GX enables users to input bending parameters directly into its user-friendly interface. This includes specifying each bend's desired angle, radius, and other essential parameters. Once the parameters are set, the machine executes the bends precisely according to the programmed specifications.

The Greenlee 855GX allows you to preset bending angles into its memory, enabling the bender to automatically stop at the programmed angles.

Check out this demonstration by Greenlee on how to bend a 90° on a 2” EMT.

If you need more detailed instructions, be sure to read the 855GX IntelliBENDER® Electric Bender manual.

Greenlee 855GX Overview and Capabilities

Greenlee 855GX Features

The Greenlee 855GX is Greenlee's most advanced programmable bender, capable of handling complex bends with ease and speed.

One shoe can bend 3/4" Rigid and 1" to 2" Rigid, EMT, or IMC conduit. Equipped with smart sensors, it automatically detects the conduit type and size, factoring in spring-back for precise angles. With a durable pendant controller and a user-friendly LCD interface, operators can easily program, save, and transfer multiple bends using a USB drive, making it an invaluable tool for projects requiring a variety of bends in large quantities.

Ready in Two Steps - Set Shoes, Choose Angle, Bend Away!

When it comes to switching between horizontal and vertical bending, the Greenlee 855GX makes it easy. With its pivoting cylinder, you're ready to bend in just a few seconds. It also has a sturdy pendant controller and a cutting-edge LCD interface to save and transfer multiple bends.

Get the Job Done 4X Faster

The Greenlee 855GX is lightning fast, making any bend a piece of cake - even those tricky 3D bends. And It's all managed through a user-friendly and smart LCD. You can even save your favorite bends and replicate them on other 855GXs. Save your bends on a USB drive and be prepared for jobs that demand top-notch bends of all types.

NOTE

Although the Greenlee 855GX has a digital LCD, you can manually bend the conduit with the regular pendant.

Precision Matters - Say Goodbye to Wasted Time and Materials

With the 855GX by your side, you'll tackle the most complicated bends easily and quickly. This powerhouse can bend 3/4" Rigid (using either the 1" Rigid or 1" EMT shoe grooves) and 1" to 2" Rigid, EMT, or IMC conduit with just one shoe. Thanks to its absolute encoder-based system and bending tables, the unit knows precisely where the shoe is positioned. It even takes care of spring back automatically and communicates bend marking dimensions—no more guesswork or rework— precision at its finest.

Reliability is the Name of the Game

Built to withstand the most demanding jobs, the Greenlee 855GX boasts a rugged frame and drive train construction that ensures consistent bending performance for the long haul. And check out the newly-designed pendant controller - those tactile feedback buttons and rare earth magnets mean it'll stay firmly in place no matter what.

No arcing or potential relay failure here. With its robust solid-state electrical system, the 855GX can handle a variety of job site power sources without breaking a sweat. And let's not forget the built-in storage, braking system, and forklift tubes - all for added flexibility and mobility around the job site.

Get ready to conquer any bending task with the Greenlee 855GX by your side. It's rugged, precise, and reliable, just like the hardworking folks who use it daily.

Individual Feature Points

Programmable Touchscreen Interface: The Greenlee 855GX has a user-friendly interface that simplifies setup and customization. Electricians can easily input bending parameters, such as angle and radius, directly on the touchscreen. This intuitive interface streamlines the bending process and eliminates the need for manual calculations.

Advanced Bending Algorithms: The machine's intelligent software calculates and executes complex bends accurately, minimizing errors and rework. This feature is great for projects that require multiple bends or intricate configurations.

Check out this video to learn more about programming advanced bending algorithms with the Greenlee 855GX.

Wide Compatibility: The Greenlee 855GX is compatible with various conduit materials and sizes. It can handle 3/4" to 2" rigid conduit, 1" to 2" EMT conduit, and 1" to 2" IMC conduit. This versatility allows electricians to tackle various types of projects without the need for multiple bending tools.

Safety Features: The Greenlee 855GX prioritizes built-in safety features. It includes an auto-stop mechanism that halts the bending process if anomalies or issues are detected. This helps prevent accidents and damage to the machine or conduit. Additionally, the error-detection mechanisms ensure bends meet specifications and reduce the likelihood of errors in critical applications.

These specific features of the Greenlee 855GX contribute to its efficiency, precision, and safety.

The programmable touchscreen interface simplifies setup and customization, while the advanced bending algorithms deliver consistent and accurate bends. Its wide compatibility ensures versatility, accommodating different conduit materials and sizes.

Lastly, including safety features provides peace of mind and promotes a secure working environment for electricians.

Behind the Performance: Greenlee 855GX Specifications

The Greenlee 855GX is a true powerhouse. It’s designed to deliver exceptional performance and reliability and stands at the forefront of precision engineering. With its impressive array of specifications, the Greenlee 855GX sets a new standard in versatility and efficiency. From its robust construction to its cutting-edge features, every detail has been meticulously crafted to meet the demands of the most challenging tasks.

Greenlee 855GX Specifications

| Amperage Rating | 20 AMP GFCI Protected Receptacle |

| Bend Radius | 7.000" (177.800 MM) - 9.000" (228.600 MM) (EMT, IMC Rigid) For 1.000" - 2.000" Shoe Size |

| Height (vertical bending position) | 117.1 cm (46.1") |

| Width | 74.7 cm (29.4") |

| Depth (vertical bending position) | 84 cm (33.0") |

| Mass/Weight (bender with shoes and roller supports) | 230 kg (507 lb) |

| Standard | C/US UL Listed |

| Type | Programmable |

| Voltage Rating | 120 VAC |

| Capacity | 3/4" - 2" Rigid, 1" - 2" EMT, IMC |

| Sub Brand | IntelliBender |

The chart below provides essential information on the recommended bending radii for each conduit type and size, ensuring accurate and efficient bending operations. Whether you're working with EMT, IMC, Rigid, or PVC Coated conduit, this chart is your indispensable guide to achieving precise bends with the 855GX.

| 855GX BENDING RADII | |||

|---|---|---|---|

| Conduit Size | Conduit Type | Inches | mm |

| 1” | EMT | 7 | 177.8 |

| 1-¼” | EMT | 8-13/16 | 223.8 |

| 1-½” | EMT | 8-3/8 | 212.8 |

| 2” | EMT | 9-1/4 | 235.0 |

| 3/4" | Rigid | 6-13/16 | 173.0 |

| 1” | IMC/Rigid | 6-15/16 | 176.2 |

| 1-¼” | IMC/Rigid | 8-3/16 | 208.0 |

| 1-1/2 | IMC/Rigid | 8-1/4 | 209.6 |

| 2” | IMC/Rigid | 9 | 228.6 |

| ½” | PVC Coated | 4-1/2 | 108.0 |

| ¾” | PVC Coated | 5-7/16 | 138.1 |

| 1” | PVC Coated | 6-15/16 | 176.2 |

| 1-1/4 | PVC Coated | 8-3/4 | 222.3 |

| 1-1/2 | PVC Coated | 8-1/4 | 209.6 |

| 2” | PVC Coated | 9 | 228.6 |

These specifications provide an overview of the bending capacity, power requirements, and important technical details of the Greenlee 855GX. It is recommended to consult the manufacturer's documentation or official specifications for precise dimensions and weight information.

How to Program a Bend with the 855GX

Note that the programmed angles take spring back into account.

Here's how you can program a basic bend:

- Select the desired angle by using the angle selection buttons on the pendant. A single press adjusts the angle by 1°, while holding the button down rapidly increases the angle in 5° increments. Pressing "CLEAR" resets the programmed angle to 0°. The programmed angle remains in memory until cleared, a new angle is selected, or the power is turned off.

- Press the "BEND" button until the bender stops. It's normal for the bender to slow down before reaching the selected angle. Once the bender stops at the programmed bend, the pendant display blinks twice to indicate the programmed angle. To continue bending, reset the programmed angle with the "CLEAR" button or increase it beyond the actual shoe angle using the angle selection buttons.

The Greenlee 855GX's computer functionality allows you to program and layout bends accurately. Here's how to perform a fully programmed bend:

- Press the "PROG BEND" button to initiate the programming process.

- Choose the conduit type on the LCD screen that matches the one you'll be using, or load a saved bend from a USB thumb drive.

- Select the conduit size on the LCD screen corresponding to your chosen conduit.

- By pressing the corresponding button, Determine the type of bend you want to make (e.g., stub/kick, offset, saddle, U-bend).

- Input the dimensions of the bend, such as height, length, and angle, using the buttons on the bender's interface.

- Press "NEXT" to proceed or "BACK" to return to the previous screen.

- Place marks on the conduit based on the stated distances.

- Save the programmed bend to the bender's local memory by pressing "SAVE," or save it to a USB thumb drive by pressing "SAVE USB." Alternatively, press "NEXT" to begin making the programmed bend or "BACK" to return to the previous screen.

- Load the conduit and align the front of the hook with the first mark. Press the "BEND" button until the bender stops. Repeat the process for subsequent marks until the display shows "BENDING COMPLETE."

By following these steps, you can take full advantage of the Greenlee 855GX's programming capabilities, streamlining your bending process and achieving accurate results.

Note

This bender will actively prevent users from changing machine settings outside of -10 and -2 degrees.

Greenlee 854DX: An Affordable Alternative

The Greenlee 854DX is a versatile conduit bender that offers a reliable and cost-effective option for professionals needing a bending solution. While it may not have all the advanced features of its counterpart, the 854DX serves as a practical alternative.

Unlike the programmable bending capabilities of the 855GX, the 854DX offers non-programmable bending. This means that each bend needs to be set up manually, making it more suitable for more straightforward bending tasks that don't require complex configurations or repetitive bends. While it may lack the automation and precision of the 855GX, the 854DX still delivers consistent results within its capabilities.

One of the key advantages of the Greenlee 854DX is its affordability. It provides a budget-friendly option for electricians and professionals who prioritize cost-effectiveness without compromising quality. The 854DX offers reliable bending performance at a more accessible price point, making it an attractive choice for those with tighter budgets or specific project requirements that don't necessitate programmable features.

Check out this specification chart below to compare the two machines.

| Greenlee 855GX | Greenlee 854DX | |

| Centerline Bend Radius | 7.000" (177.800 MM) - 9.000" (228.600 MM) (EMT, IMC Rigid) For 1.000" - 2.000" Shoe Size | 4.25" (108 MM) - 9" (228.6MM) (EMT, IMC Rigid) For 1/2" - 2" Shoe Size |

| Voltage Rating | 120 VAC | 120 VAC |

| Conduit Size | 3/4" to 2" Rigid 1" to 2" EMT & IMC | 1/2" to 2" Rigid, EMT, & IMC |

In summary, the Greenlee 854DX offers a cost-effective alternative with its affordability and reliability, although it lacks the advanced programmable bending features found in the 855GX model. Professionals looking for a budget-friendly bending solution without sacrificing quality will find the 854DX advantageous.

Conclusion

Overall, the Greenlee 855GX Smart Bender revolutionizes the world of conduit bending with its advanced technology and exceptional efficiency gains. The programmable capabilities eliminate guesswork and enable electricians to achieve accurate and consistent results, even with complex bends. Its user-friendly interface and versatile bending capabilities make it an invaluable tool for any bending task.

Meanwhile, the Greenlee 854DX offers a cost-effective alternative for simpler bending needs. Both machines provide reliable performance and contribute to increased productivity in the field. Whether you choose the high-end 855GX or the budget-friendly 854DX, Greenlee ensures that your bending operations are streamlined and precise. Mitigate manual bending struggles and say hello to the efficiency of smart technology with Greenlee.

Greenlee 855GX Frequently Asked Question

What types of conduit materials are compatible with the Greenlee 855GX?

The Greenlee 855GX is compatible with various conduit materials, including rigid, EMT, and IMC conduit.

Can the Greenlee 855GX be used for both residential and commercial applications?

Yes, the Greenlee 855GX is designed for various residential, commercial, and industrial applications.

How does the Greenlee 855GX minimize the risk of spring back during the bending process?

The Greenlee 855GX incorporates advanced algorithms and precise controls to account for spring back. The machine automatically adjusts the bending parameters to compensate for spring back, resulting in accurate and predictable bends.

Can the Greenlee 855GX be used with conduit materials other than rigid, EMT, and IMC?

The Greenlee 855GX is specifically designed for use with rigid, EMT, and IMC conduit materials. It is recommended to consult the manufacturer's documentation or seek expert advice for other conduit material compatibility.

What is a common hazard associated with pipe bending?

One common and significant hazard when working with piping during bending is the risk of cuts or lacerations. It is crucial to avoid touching the tube surface, whether with or without gloves, to prevent potential injuries.