Table of contents

The ability to control hazardous energy on the worksite is an important part of maintaining the safety of all team members, particularly in industries with heavy machinery that are often serviced or need to be maintained frequently. Severe injuries or fatalities most commonly occur when unexpected startup or release of stored energy from electrical, hydraulic, or mechanical sources suddenly happens. This is why OSHA mandates Lockout Tagout (LOTO) procedures to reduce these risks by making sure that there is a systematic approach to disabling equipment and preventing energy releases.

MasterLock has established itself through the years as a trusted provider of Lockout Tagout solutions. They offer professional locks and other accessories that help maintain safe compliance with OSHA standards and international safety regulations. From robust padlocks with Zenex Thermoplastic or laminated steel bodies to comprehensive kits, MasterLock’s range can adapt to the demands of expert industrial needs. MasterLock's Lockout Tagout kit also features color-coded locks for easier and more coordinated visual identification.

Customizable options further set MasterLock apart by allowing professionals to choose from various shackle heights, materials, and other keyed configurations, including keyed alike, keyed differently, or master key systems. It's nice to have these adaptable solutions because they apply effective energy control programs by not only meeting regulatory requirements but also integrating seamlessly into the already existing safety protocols within the company.

Below is a quick video overview of MasterLock's OSHA Lockout Tagout system.

Understanding Lockout Tagout (LOTO)

Lockout Tagout is a safety procedure that's used to make sure that dangerous machinery in warehouses and other construction sites is properly shut off and cannot be turned on again before workers have finished maintenance or servicing it. This procedure requires that hazardous energy sources are isolated by using lockout procedures. These procedures render the heavy machinery inoperable without power before work is started on the equipment.

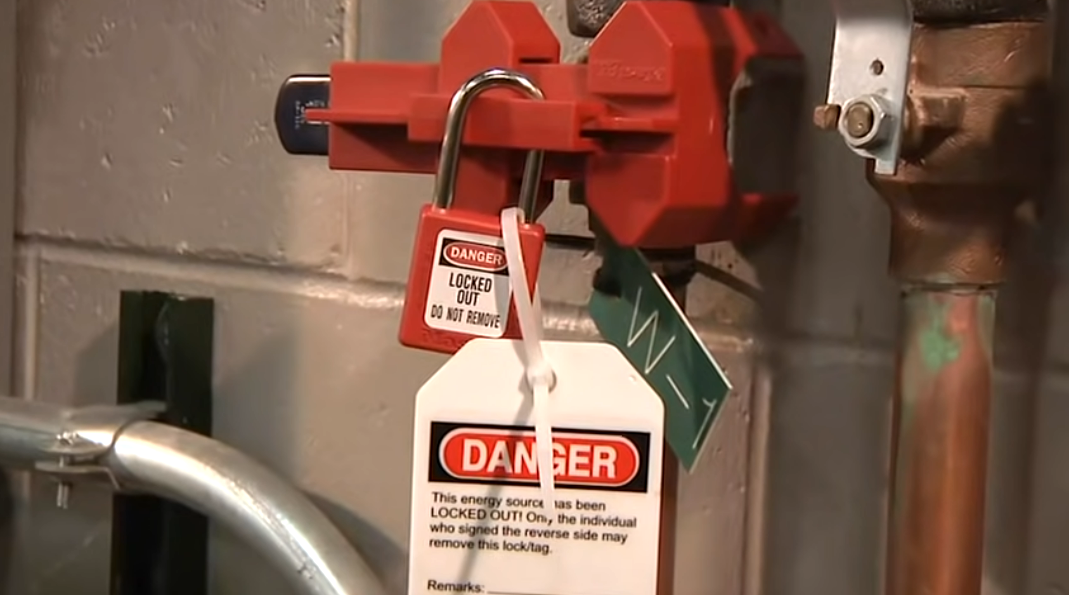

- The "Lock Out" component involves physically locking the energy-isolating machine to prevent the unexpected release of hazardous energy (ensuring that the machine can't start up again).

- The "Tag Out" aspect involves placing a tag on the locked device to warn others not to operate the equipment (Also letting others know who locked out the machine).

Lockout Tagout procedures can be applied to various energy sources on the jobsite, including electrical, mechanical, hydraulic, pneumatic, chemical, and thermal machines.

OSHA Requirements

The Occupational Safety and Health Administration (OSHA) has established specific standards for controlling hazardous energy, known as the LOTO standard (29 CFR 1910.147). This standard outlines the minimum requirements for controlling hazardous energy while servicing and maintaining machines and equipment.

Employers must create, implement, and enforce a thorough energy control program and train all employees on what to look for. This includes developing specific procedures for each piece of equipment. Only authorized employees with the necessary training are allowed to perform LOTO procedures. Additionally, periodic inspections should be conducted to ensure these procedures are properly followed.

OSHA Regulation Requirements |

MasterLock Lock Out Tag Out Features |

Durability: Locks and other products must be made with materials that can handle the environment |

Yes, MasterLock offers padlock materials such as Zenex Thermoplastic, Aluminum, or Laminated Steel lock bodies |

Fortified and Substantial: Unless substantial force is applied, they cannot be taken off or removed |

Yes, MasterLock padlocks are fortified |

Identified: Tags help identify the employee that is using the LOTO system |

Yes, MasterLock includes tags to help identify employee’s |

Made for Lock Out Tag Out ONLY: Only use these for controlling energy and not other locking needs, i.e., lockers or toolboxes |

Yes, MasterLock LOTO should only be used for controlling energy |

MasterLock Lock Out Tag Out Solutions

MasterLock offers an extensive range of LOTO products designed to meet the diverse needs of various trade industries and jobs. Their product line includes:

- Safety padlocks in various sizes and materials

- Lockout hasps for multiple lock applications

- Valve lockouts for different valve types

- Electrical lockouts for circuit breakers and

- Lockout stations and kits for organized storage and portability

MasterLock has introduced the No. 1-S3068 Seal Tight Handle-On Ball Valve Lockout, a versatile solution for severe lockout tagout applications. Built with durable aluminum and steel, this patent-pending device resists corrosion and withstands extreme temperatures, ensuring reliable performance in harsh environments. Its lightweight, compact design clamps securely onto the handle stop to prevent valve movement, accommodating valve sizes from 1/4 inch (6mm) to 4 inches (102mm). Ideal for use on insulated pipes and in tight spaces, it works seamlessly with all MasterLock safety padlocks and lockout hasps, making it a portable and efficient choice for valve lockout needs. Mayo Hardware safety product manager Jason Vandenberg says, “Used properly in conjunction with a well-planned lockout process, Master Lock safety padlocks and lockout accessories help organizations protect their employees with a complete Lockout Tagout solution.”

Key features of MasterLock Lock Out Tag Out devices

MasterLock's Lockout Tagout kits are created with several key features that set them apart from the competition:

- Durability: These padlocks are made from high-quality materials, like Zenex thermoplastic body, for superior performance in harsh, rugged environments. They're also made to withstand chemical exposure on the jobsite and extreme weather conditions.

- Standardized colors and shapes: By having different colors and shapes, workers can easily identify different lockout devices and their purposes.

- Keyed-different locks: Ensures that each authorized worker has a unique key for their personal safety padlock.

MasterLock 1457E410KA Personal Electrical Lockout Kit

The MasterLock 1457VE410KA Lockout Kit incorporates everything you need for most lockout tagout jobs into a single, portable case. This kit includes keyed-alike Zenex padlocks for quick on-the-job access, adjustable lockouts for odd-shaped areas, and multiple valve covers to handle everything from gate valves to ball valves. Another reason this kit is so helpful is that it keeps you more organized. No more scrambling around the worksite or inside your toolbox to find the right tool in the middle of a job. This compact kit is designed specifically for electrical LOTO procedures, and it contains:

- 410RED Zenex thermoplastic padlock

- 420 aluminum lockout hasp

- S2390 Grip Tight circuit breaker lockout

- 491B rotating electrical plug lockout

- 497A wall switch lockout

- Lockout tags and ties

Benefits of this kit include:

- Portability: Comes in a compact carrying case for easy transport.

- Completeness: Contains all necessary tools for most electrical lockout scenarios.

- Durability: High-quality parts and accessories that are designed for frequent usage.

The Pros of Personal Lockout Kits

Personal lockout kits offer several advantages in implementing effective LOTO procedures:

- Accessibility: Ensures each worker has immediate access to necessary LOTO devices

- Accountability: Personal kits encourage individual responsibility for safety procedures

- Efficiency: Reduces time spent locating and gathering LOTO equipment

What's in a MasterLock Lock Out Tag Out Kit?

Padlocks

MasterLock safety padlocks are designed to meet OSHA lockout tagout requirements and are durable enough to secure hazardous energy sources.

Available in various sizes and materials, such as Zenex thermoplastic, anodized aluminum, and laminated steel, these padlocks are built to withstand harsh environments on the jobsite, regardless of the conditions. They also come with color-coding options (e.g., red for electrical, blue for pneumatic) to help standardize lockout procedures and visually identify departments or hazards based on the company's rules and details. Keyed-different configurations ensure individual worker safety, while other options like keyed-alike or master-keyed support flexible lockout scenarios in case others need to use or have access to the locks (specifically managers or shift change). Shackle materials and sizes vary, including plated metal, stainless steel, nylon, boron, and hardened steel, with heights ranging from 0.75" to 3" and diameters for different applications.

MasterLock padlocks include lightweight, non-conductive thermoplastics and heavy-duty steel options. This makes them an ideal choice because they maintain OSHA compliance and safety in industrial settings.

In short, these padlocks feature:

- Various sizes to accommodate different lockout points

- Made from durable materials like Zenex thermoplastic or aluminum

- Color-coded for easy identification (e.g., red for electrical, blue for pneumatic)

- Keyed-different for individual worker safety

Lockout Devices

MasterLock lockout devices provide users with a range of solutions to secure hazardous energy sources during maintenance and repairs. Circuit breaker lockouts can accommodate several different breaker types and sizes, while valve lockouts are made for ball, gate, and butterfly valves. Masterlocks's plug and switch lockouts ensure power sources stay disconnected to prevent accidental reconnection and danger. For professionals who deal with larger electrical panels, multi-pole breaker lockouts offer reliable, better security, helping experts maintain safety and compliance on the job.

- Circuit breaker lockouts: Fit various breaker types and sizes.

- Valve lockouts: Designed for ball valves, gate valves, and butterfly valves.

- Plug and switch lockouts: Prevent accidental reconnection of power sources.

- Multi-pole breaker lockouts: Secure larger electrical panels.

Hasps and Tags

MasterLock tags and hasps are important parts of any lockout kit because they make sure that there is clear communication among the worksite and that there are secure, identifiable lockout points. Steel or aluminum hasps enable multiple workers to lock a single energy source, confirming that no one can remove a lock before it should be. "Danger Do Not Operate" tags provide explicit warnings, while write-on tags allow customized instructions or identification to be added. These tools are one of the main ways to prevent accidents, maintain compliance, and keep teams safe during maintenance or repairs.

Steel or aluminum hasps allow multiple locks on a single lockout point

“Danger Do Not Operate" tags provide clear visual warnings

Write-on tags for customized information and instructions

Choosing the Right MasterLock Lock Out Tag Out Kit

Factors to consider

- Type and variety of equipment in the workplace

- Number of employees requiring Lockout Tagout access

- Frequency and complexity of Lockout Tagout procedures

- Industry-specific requirements or regulations

MasterLock kit options:

- Personal kits for individual workers in specific trades (Electrical or Valve)

- Department-specific kits for areas like electrical or mechanical maintenance

- Facility-wide kits for wide coverage of all potential lockout scenarios (With other accessories available for separate purchase)

Best Practices for LOTO Implementation

Training and Education

Focusing on training and education for lockout tagout (LOTO) is important for workplace safety and OSHA compliance. Initial training on the jobsite ensures that every employee understands the importance of lockout tagout procedures and that they understand and are aware of all potential hazards.

Specialized training for authorized personnel performing lockout tagout procedures gives them the skills and knowledge to safely perform the lockout processes. It's also a good idea to have regular refresher courses to help them maintain proficiency and reinforce best practices on the worksite. By doing this, professionals can reduce the risk of accidents caused by complacency or outdated knowledge. Consistent safety education promotes a culture of safety and accountability across the workplace.

- Initial training for all employees on Lockout Tagout Awareness

- Specialized training for authorized employees performing Lockout Tagout procedures.

- Regular refresher courses to maintain knowledge and skills

Regular inspections and audits

Regular inspections and audits are essential for maintaining the effectiveness of MasterLock lockout tagout (LOTO) programs when working on job sites. Having these periodic reviews ensures safety procedures remain accurate and up-to-date on current regulations and relevant for each piece of equipment. It's also good to have annual or more frequent audits to evaluate the program’s overall effectiveness. Documenting inspections and corrective actions creates a record of compliance. It highlights areas for improvement, and it's especially helpful for workers to see what can be improved upon by helping to prevent safety lapses and confirming that they are adhering to regulations.

Periodic review of Lockout Tagout procedures for each piece of equipment

Annual (or more frequent) audits of Lockout Tagout program effectiveness

Documentation of all inspections and corrective actions

Proper storage and maintenance of MasterLock Lock Out Tag Out devices

Proper storage and maintenance of lockout tagout (LOTO) devices are essential for ensuring they function reliably when needed. Dedicated storage areas keep LOTO equipment organized and easily accessible, reducing downtime when looking for them. Regular inspections help identify wear or damage, ensuring devices remain in safe working condition for all users. Quickly replacing any damaged or lost components can prevent delays in any machine maintenance and maintain compliance, helping to protect workers and secure hazardous energy sources effectively.

- Dedicated storage areas for Lockout Tagout equipment

- Regular inspection of devices for wear or damage

- Prompt replacement of damaged or lost Lockout Tagout components

Closing the Loop on Workplace Safety with Master Lock

Overall, implementing MasterLock's Lockout Tagout (LOTO) solutions is a crucial step in maintaining a safe and compliant work environment. With their durable, customizable, and comprehensive range of LOTO products, MasterLock ensures that teams have the right tools to control hazardous energy sources and prevent accidents.

By following OSHA guidelines, choosing the appropriate lockout kits, and incorporating best practices such as proper training, regular inspections, and efficient storage, businesses can significantly reduce the risk of injuries and fatalities on the job. MasterLock’s commitment to safety and adaptability makes it a trusted partner in building a secure and efficient workplace for all employees.

MasterLock Lockout Tagout Frequently Asked Questions

What is Lockout Tagout (LOTO)?

Lock-out tag-out (LOTO) is a safety procedure used to ensure that machinery or equipment is properly shut off and cannot be restarted until maintenance or servicing is complete. This prevents accidental start-ups that could cause injury. LOTO typically involves locking devices and tagging mechanisms to communicate the locked-out status.

Are Master Lock LOTO products OSHA-compliant?

Yes, Master Lock LOTO products are designed to meet OSHA’s standards (29 CFR 1910.147), which specify requirements for controlling hazardous energy during maintenance and servicing.

What are the differences between the padlock materials (steel, aluminum, plastic)?

- Steel: High-security and durable, ideal for tough environments.

- Aluminum: Lightweight but strong, resistant to corrosion.

- Plastic/Non-conductive: Best for electrical applications where conductivity needs to be avoided.

How do color-coded locks help in LOTO procedures?

Color-coding allows for easy identification of who is responsible for the lockout or which team it belongs to. For example, each maintenance worker might have a specific color, reducing confusion and enhancing accountability.