Table of contents

RIDGID 300 Pipe Threader: Enhancing Productivity with Unmatched Performance

Pipe threading is a critical process in plumbing, mining, heavy industrial applications, and more industries. It ensures secure and reliable connections between pipes, allowing for efficient fluid or gas flow and preventing leaks.

The RIDGID 300 Complete Threading Machines offer advanced features and capabilities for professional pipe threading. There are two different models (15722) and (15682), with the spindle speed being the differing factor.

Before making a purchase, it's crucial to consider factors such as the size of the threader, the types of threads it can handle (such as NPT, BSPT, or metric threads), overall quality, warranty, and the availability of replacement parts. Additionally, understanding the specific needs of your project, including the pipe diameter, material, and threading specifications, will help you decide whether the RIDGID 300 pipe threader machine is what you need.

Learn about the RIDGID 300 Complete Threading Machines in under 1 minute with this video:

This article will focus on the two RIDGID 300 pipe threader models and provide a comprehensive comparison. We will discuss their key features and differences, specifications, and suitability for various applications.

Let's dive in and find the perfect pipe threader to elevate your project to new heights.

What is the RIDGID 300 Pipe Threading Machine

The RIDGID Model 300 Power Drive Complete is a motorized pipe threader designed to simplify creating threads on pipes. Its primary purpose is to prepare pipes for assembly by creating threaded ends, enabling secure connections, and preventing leakage.

This powerful machine can handle a wide range of pipe sizes, from 1/8 inch to 2 inches in diameter, and can thread pipes made of various materials, including steel, stainless steel, and plastic.

The Model 300 Power Drive Complete incorporates advanced features to enhance efficiency and ease of use. Equipped with a high-torque motor, it creates threads and grooves on the ends of pipes, similar to the threading found on a screw. This allows workers to connect pipes to connectors or couplings securely. The threaded ends of the pipe interlock with the threads on the coupling, creating a sturdy and durable connection. The motor's high torque ensures clean and accurate thread cutting.

Watch this short video on how to thread pipe with the RIDGID 300.

The tool also includes a reversible direction switch, eliminating the need for complex adjustments when threading both right-handed and left-handed pipes. This time-saving feature simplifies the threading process and improves overall efficiency.

In terms of setup and mobility, the Model 300 Power Drive Complete offers convenience. Its compact and portable frame allows for easy transportation between job sites. The tool can be securely mounted on a sturdy workbench or used with a compatible RIDGID tripod for stability during operation.

Overall, the RIDGID Model 300 Power Drive Complete is a reliable and versatile pipe threader that streamlines the threading process.

The History of RIDGID Pipe Threading

In 1948, the pipe threading industry experienced a significant breakthrough when Ridge Tool Company introduced the RIDGID 400 Power Drive. This electric portable power drive revolutionized the slow and tedious hand threading process, providing a much-needed boost to efficiency and productivity.

The RIDGID Model 500 Threading Machine, introduced in 1950, revolutionized pipe threading operations by combining cutting, reaming, and threading capabilities into a versatile unit. Building on its success, the Model 535 Pipe and Bolt Threading Machine, launched in 1957, set the industry standard with its patented RIDGID Speedchuck, offering a secure grip on materials.

The RIDGID 300 was introduced in 1959, further improving pipe threading operations. This machine simplified threading, reaming, and cutting tasks while providing a lightweight and portable solution. It could be easily mounted on a truck or stand, offering convenience and flexibility for professionals working on various projects.

Bezz from the United Kingdom said, “I've used RIDGID 300s since the first days of my apprenticeship, beginning in 1976. These machines are truly wonderful, easy to use and extremely robust. Whatever you throw at them, they shrug it off. Dependable and powerful, the 300 is just perfect for all pipework requirements. I've had the misfortune to use "other" makes that look suspiciously alike the 300 and there is no comparison. The 300 is a true masterpiece, copied by some, rivalled by none.”

Over the years, the iconic RIDGID 300 has undergone updates while steadfastly maintaining its position as a standard in the plumbing industry.

These advancements demonstrate the industry's commitment to improving performance, efficiency, and user experience. With various innovative tools, pipe threading operations are significantly simplified, contributing to professionals' success.

RIDGID 300 Pipe Threader Model Differences: Exploring the Variations

The RIDGID 300 COMPLETE series offers a range of options tailored to meet specific requirements. Among these options, the RIDGID 15682 300 complete (38 RPM) Pipe Threading Machine and the RIDGID 15722 300 complete (57 RPM) Pipe Threading Machine stand out as two distinct models.

While both machines share the reliability and efficiency associated with the RIDGID brand, their rotational speed capabilities differ, which can significantly impact productivity and the types of applications they excel in.

This section will explore the differences between these two models, shedding light on their strengths and what is included within the package.

Check out this How To video provided by RIDGID to get an overview perspective:

What's included with the Model 300

- 300 Power Drive with Foot Switch

- Set 1/2" - 3/4" Universal Alloy Dies

- Set 1" - 2" Universal Alloy Dies

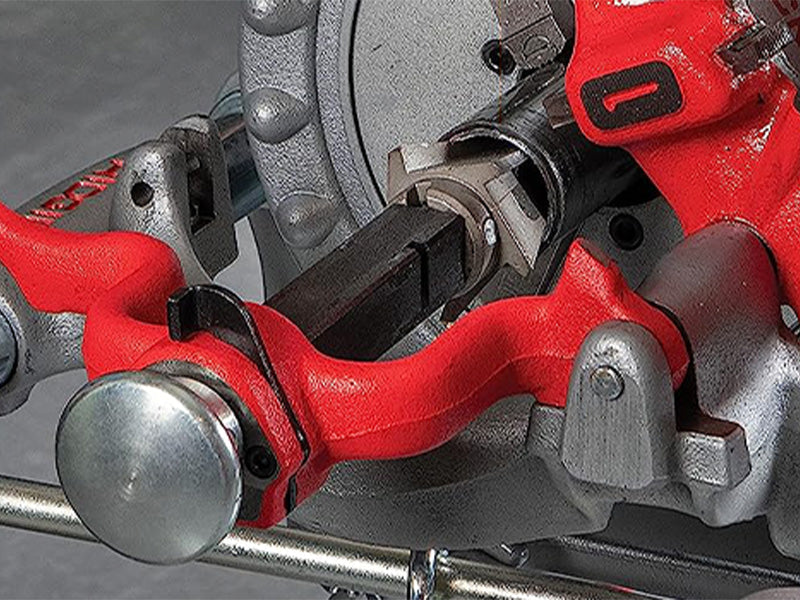

- 311 Carriage with Lever

- 811A Universal Die Head

- 32 Transporter

- 1452 Removable Tray

- 1206 Stand

- Reamer

- 360 Cutter

- 418 Oiler

Key Differences

The differences between the RIDGID 15722 300 COMPLETE (57 RPM) Pipe Threading Machine and the RIDGID 15682 300 COMPLETE (38 RPM) Pipe Threading Machine are:

- RPM (Rotations Per Minute): The RIDGID 15722 operates faster with a rotational speed of 57 RPM, while the RIDGID 15682 operates at a slightly slower speed with a rotational speed of 38 RPM. This difference in RPM can impact the rate of pipe threading operations and die lifespan. Depending on the material used, the pace should be slower or faster.

-

ROD Threading Capacity:There is a slight difference in thread pulling capacity shown below

- The RIDGID 15722: in. ¼ - 1 ½

- The RIDGID 15682: in. ¼ - 2

To understand the differences, consider watching this video on threading steel pipe with a RIDGID 300 power drive machine.

Considering these differences and evaluating your requirements is important to determine which machine suits your pipe threading needs better.

RIDGID Model 300 Threader (57 RPM)

The RIDGID 15722 (57 RPM) Pipe Threader Machine , with its high rotational speed of 57 RPM, offers several advantages for faster threading tasks. This machine is designed with precision and versatility to handle pipes of various sizes and materials, making it suitable for a wide range of industrial and construction applications.

The 57 RPM option is particularly beneficial in time-sensitive projects with tight deadlines. The faster RPM significantly reduces the time required to complete the pipe threading.

The higher RPM proves invaluable when dealing with a large volume of pipes, such as in industrial applications or large-scale plumbing projects. It expedites the threading process, allowing more pipes to be threaded within a given time frame. This increased productivity not only saves time but also reduces labor costs.

IMPORTANT

However, it's important to note that while the higher rotational speed of 57 RPM expedites operations, it also means that the dies used in the threading process may have a shorter lifespan. The increased speed tends to wear out the dies quicker, necessitating more frequent replacements. This consideration should be considered when evaluating the machine's cost-effectiveness and overall maintenance requirements.

The 57 RPM option is compatible with softer pipe materials like plastic or non-ferrous metals. The faster rotation helps prevent these materials from melting or deforming during the threading process. It ensures clean and accurate threads, maintaining the integrity of the pipes.

RIDGID 15722 Features

And it also includes:

- RIDGID speed chuck

- Reversible 1/2 HP universal motor

- Recessed On/Off/Reverse switch

- CSA approved

- Approved to UL standards ( NRTL )

RIDGID 15722 Specifications

| Motor | 1/2 HP, universal, reversible motor, single-phase |

| Volts | 115V, 25-60HZ |

| Weight |

|

| Switch | Heavy-duty FOR/OFF/REV and Integral Foot Switch |

| Chuck | RIDGID speed chuck with replaceable rocker-action jaws |

| Spindle Speed | 57 RPM |

| Pipe Threading Capacity | 1/8" - 2" (3-50 mm) |

| Rod Threading Capacity | 1/4" - 1" - 1/2" (6-40 mm) |

| Max Geared Threader Capacity | 6" (150 mm) |

RIDGID Model 300 Threader (38 RPM)

The Ridgid 300 pipe threader also offers a lower RPM option of 38, which proves advantageous in specific circumstances where precision and control are prioritized. Let's explore these scenarios further:

When working with harder pipe materials like steel or stainless steel, a slower RPM of 38 is often preferred. Slower rotation allows for more controlled cutting, reducing the risk of overheating, chatter or damaging the pipe's integrity. This lower speed ensures that precision and accuracy are maintained during the threading process, resulting in clean and precise threads.

Certain delicate or thin-walled pipes require a more careful approach to avoid damage. The slower RPM of 38 gives the operator greater threading control in such cases. This controlled rotation minimizes the risk of cracking, denting, or damaging the surface of the pipe.

A slower RPM is favored for optimal results if you are threading tapered pipe threads, such as NPT (National Pipe Taper) threads. The gradual engagement of the threads is crucial to ensure a tight and secure fit between the threaded components. The slower rotation speed of 38 RPM allows the operator to carefully engage the threads, creating a reliable and leak-free connection.

The lower RPM option of 38 for the Ridgid 300 pipe threader proves beneficial when precision, control, and the pipe's integrity are paramount. Whether working with harder materials, delicate pipes, or tapered threads, the slower rotation speed ensures accurate threading and minimizes the risk of damage or compromised connections.

RIDGID 15682 Features

- Heavy-Duty Proven Performance

- Lightweight, Portable Design, Fast Transport, and Set

- Self-Contained Oil System with adjustable flow control

- Versatility for Threading and Grooving

- Quiet Operation

RIDGID 15682 Specifications

| Motor | 1/2 HP, Universal, reversible single-phase |

| HZ | 25-60, 115V |

| Capacity | 1/8" - 2" |

| Switch | Recessed On/Off/Reverse |

Applications for the Model 300 Threader

The RIDGID 15722 300 (57 RPM) Pipe Threading Machine and the RIDGID 15682 300 (38 RPM) Pipe Threading Machine can be used in various applications. Here are some specific examples of where each machine may be suitable:

RIDGID 15722 300 COMPLETE (57 RPM) Pipe Threading Machine:

- Industrial Pipe Threading: This machine's higher RPM makes it well-suited for industrial pipe threading applications where efficiency and faster operation are crucial. It can handle threading tasks on larger-diameter pipes and tough materials.

- Construction Projects: The higher RPM of this machine makes it ideal for construction projects that involve pipe installations, such as plumbing, HVAC systems, and sprinkler systems. It can help complete threading tasks swiftly and meet project deadlines.

- Pipe Fabrication: The RIDGID 15722, with its impressive RPM capability, enhances efficiency and productivity in workshops and manufacturing environments. Meticulous attention to detail is vital throughout the fabrication process, and by leveraging the faster RPM, fabricators can seamlessly execute intricate tasks, delivering superior results.

RIDGID 15682 300 COMPLETE (38 RPM) Pipe Threading Machine:

- General Plumbing: This machine's slightly lower RPM suits general plumbing tasks, such as residential or commercial pipe threading for water supply lines, drain lines, and smaller-diameter pipes. It provides sufficient speed and control for most standard plumbing applications.

- Maintenance and Repair: When performing maintenance and repair work involving pipe threading, the RIDGID 15682 can handle tasks precisely. It is well-suited for applications where a more controlled and slower threading speed is desired.

- Small-Scale Projects: If you are working on smaller-scale projects that involve pipe threading, such as home renovations or small plumbing repairs, the RIDGID 15682 can offer adequate performance and versatility.

These applications serve as examples, and the choice of machine ultimately depends on factors like pipe size, material, project requirements, and personal preference. It's always recommended to review the manufacturer's guidelines and consult with professionals to determine the most suitable machine for your specific application.

RIDGID 300 Threader Accessories

RIDGID 300 Threader Accessories offer additional functionalities and convenience to enhance the performance of both the RIDGID 300 Power Drive Complete models. Let's look closer at two specific accessories: the RIDGID 10883 Oiler with 1 Gallon Nu-Clear Thread Cutting Oil and the RIDGID 97065 811A Universal Quick Opening Right Hand Oiling Die Head.

The RIDGID 10883 Oiler is designed to provide lubrication for the threading process, ensuring smoother and more efficient operation.

It includes a hand-operated oiler that offers 50% more oil per stroke compared to other handheld oilers, resulting in longer die life.

The ergonomic 2-finger trigger design reduces user fatigue during extended use, and the die-cast heavy-duty body with a swivel nozzle and no exposed parts contributes to the product's durability.

Additionally, the oiler features a reservoir with a removable chip tray, a 54" hose, and a fastenerless twist and lock drip pan that securely attaches to the reservoir. The new material used in the reservoir is resistant to abrasion, lighter than metal, and doesn't rust, ensuring its longevity and preventing leakage or cracking.

According to Plumbersmag.com, “Threading oil plays an extremely important role in producing a quality pipe thread. The best threading oils are those produced specifically for pipe threading applications. Unlike motor oils, which are designed specifically to lubricate the moving parts of an engine, threading oils are designed for lubricating the thread, cooling the cutting surface, and removing chips.”

On the other hand, the RIDGID 97065 811A Universal Quick Opening Right Hand Oiling Die Head is a versatile accessory that offers quick and easy die changes without needing tools. This die head fits all RIDGID Power threading machines, providing compatibility and flexibility.

The quick-opening feature allows for efficient switching between different sizes of dies, saving time and effort. The die head includes a throwout lever that can be manually flipped to retract the dies once the desired thread length is cut.

With a bolt capacity ranging from 1/4" to 2" and a pipe capacity from 1/8" to 2", this die head accommodates a wide range of applications. The universal compatibility and oil-through head design further enhance its usability.

Both of these accessories, the RIDGID 10883 Oiler and the RIDGID 97065 811A Universal Quick Opening Right Hand Oiling Die Head, contribute to the overall efficiency, convenience, and versatility of both of the RIDGID 300 Power Drive Complete models.

These accessories enable smoother threading operations, reduced downtime for die changes, and enhanced durability, making them valuable additions to the RIDGID 300 threading system.

Key Takeaways

RIDGID 300 Pipe Threaders offer superior performance in pipe threading, providing a reliable and secure connection for fixing drainage lines and replacing equipment.

RIDGID's rich history of innovation backs these threaders. The RIDGID 15722 operates at a faster RPM of 57, while the RIDGID 15682 operates at an RPM of 38, and both are suitable for general plumbing and maintenance tasks. Accessories such as cutting oil and die sets are available to enhance precision. Choose the right threader and accessories for successful pipe threading.

RIDGID 300 Pipe Threader Frequently Asked Questions:

How much does a RIDGID 300 threading machine weigh?

The machine weighs 87 lbs.

What does a pipe threading machine do?

Pipe threaders are one of the essential tools that can precisely cut threads on the ends of a pipe to both the female and male attachment. It can be used in various industries, including mining, plumbing, heavy industrial applications, etc.

Are pipe threaders worth it? Is there a demand?

Yes! The Global Pipe Threading Machines Market is projected to reach US$ 45.1 Bn by 2031 from US$ 25.9 Bn in 2022. Key trends include the focus on cost-efficient and easy-to-maintain equipment, the adoption of automation technology, and the growing popularity of aluminum pipe threading machines. The market is driven by the surge in demand for portable machines for small-scale applications and the need for sturdy pipes in the oil and gas industry, offering significant opportunities for manufacturers.

Why are gas and water plumbing pipes threaded differently?

Gas pipes and water pipes have different threading directions primarily to prevent cross-threading. Gas pipes require a distinct threading direction to help plumbers quickly identify the source of gas leaks. Gas pipes are typically made of black steel for durability and corrosion resistance, while water pipes commonly use copper or PVC materials due to durability.

Can a pipe threading machine be used for other purposes besides threading?

Pipe threading machines are primarily designed for threading pipes. However, the RIDGID Model 300 Power Drive can also be a power source for roll grooving equipment. It is important to refer to the manufacturer's specifications and instructions to understand a particular threading machine's full range of capabilities.

Can a threading machine create both internal and external threads?

Yes, threading machines like the RIDGID 300 can create both internal (female) and external (male) threads on pipes. This allows for versatile connections between pipes and fittings or couplings.