Table of contents

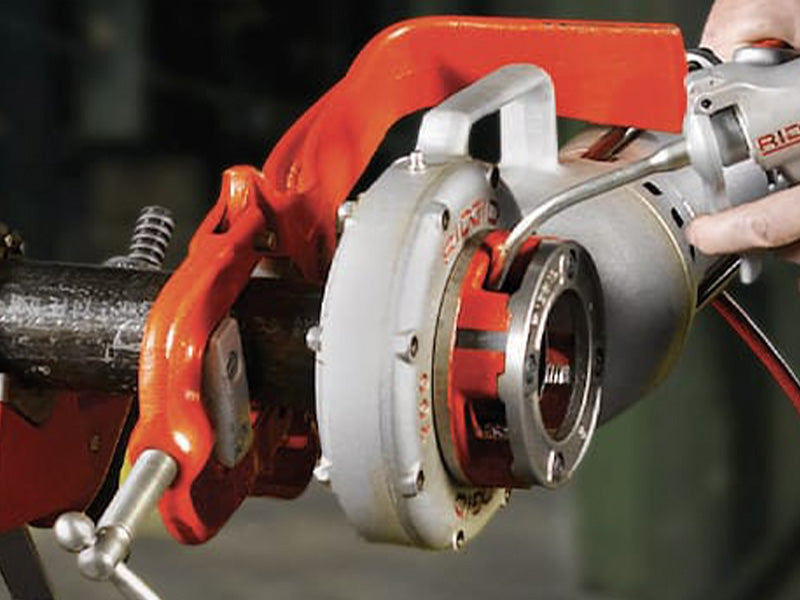

RIDGID Pipe Threader 700: Portable, Powerful, Efficient

When repairing plumbing pipes or working in smaller locations where you‘ll thread 1-1/2 pipes and sink drains, pipe threaders offer an ideal solution.

Pipe threaders play a vital role in a professionals job by cutting precise threads on both male and female pipe ends. These versatile machines find applications in diverse industries, including mining, plumbing, and heavy industrial sectors.

Choosing the right pipe threader is crucial for a smooth and efficient project. RIDGID offers a reliable solution with their standout performer, the RIDGID 700 Power Drive Pipe Threader.

The RIDGID 700 Power Drive Pipe Threader models are a cost-effective solution that delivers exceptional performance and portability. Compared to the 300 models, these tools offer hand-held applications and a more budget-friendly option without compromising efficiency. With its mobility and precision, the RIDGID 700 Power Drive tackles demanding projects effortlessly, streamlining your workflow.

In this article, we delve into the various features, benefits, and applications of these reliable tools. Discover how the RIDGID 700 Power Drive Pipe Threader can greatly enhance the efficiency of your projects, ensuring seamless connections every time. Join us as we explore the power and convenience of this remarkable machine, and experience its capabilities firsthand.

The Evolution of RIDGID Power Drives: Revolutionizing Pipe Threading

RIDGID has been at the forefront of pipe threading innovation for over seven decades, continuously revolutionizing the plumbing industry.

It all began in 1948 with the introduction of the RIDGID 400 Power Drive, a groundbreaking fusion of electric motors and hand-held tools that forever transformed threading by speeding up the once slow, tedious process. This innovation had a profound impact and set the stage for future advancements.

In the following years, RIDGID continued to push the boundaries of pipe threading technology. The iconic Model 500 Threading Machine emerged as the industry standard, maintaining its reign for over forty years. But the story doesn't end there.

In 1969, RIDGID achieved yet another milestone with the launch of the Model 700, the first-ever RIDGID Hand Held Power Drive.

Since its inception, the Model 700 has established itself as an industry workhorse, delivering unparalleled power, strength, and reliability.

This powerful machine has continuously evolved over time while maintaining its position as a staple in the plumbing industry.

Check out our RIDGID 300 pipe threader article to learn more about RIDGID's extensive pipe threading history.

What is the difference between a hand-held Pipe Threader and a Power Threading Machine?

When comparing RIDGID hand-held pipe threaders to RIDGID pipe threader machines,

there are several key differences to consider:

- Suitable for low-volume applications in service and repair

- Faster than manual threading and requires less physical effort

- Uses drop-head die heads like manual ratcheting threaders, with the difference being the power drive turns the die head around the pipe

- Offers portability but less than the manual version

- Produces a significant amount of torque, requiring a reaction arm for some applications

- Additional tools and accessories required include a pipe cutter, reamer, vise, drop head die heads, reaction arm, oiler and bucket, and threading oil

- A more expensive option but highly durable for harsh job site conditions

- Ideal for long-term use with consistent, reliable results

- Often heavy and requires mounting to a stand or other RIDGID mounting, with the pipe brought to the machine

- Operates efficiently and requires the least physical effort

- Best suited for high-volume applications as they can provide higher RPM’s compared to hand-held machines

Ultimately, the choice between hand-held pipe threaders and machine pipe threaders depends on the specific needs of your project. Hand-held threaders offer convenience and portability for smaller-scale applications, while machine threaders provide durability and efficiency for larger-scale and high-volume projects.

RIDGID 700 Pipe Threader Features

RIDGID 700 Power Drive Features:

| Pipe Capacity | 1 ⁄8"–2" (3 mm–50 mm) 1 With Geared Threaders: 21 /2″ - 6″ (141/161 Geared Threaders) |

| Gear Head | All spur gear reduction. Spring-loaded adapter pawl, hardened steel spindle gear |

| Bolt Capacity | ¼"–1" (6 mm-25mm) |

| Drive 258/258XL Pipe Cutter | Yes |

| Body and Handle | Cast Aluminum |

| Spindle Speed | 32 rpm (No load) |

| Weight (power drive only) | 25 lbs. (11 kg) |

| Length | 28¼" (71.7 cm) |

| Operating Speed (no load) | 26–30 RPM |

| Die Heads | 12-R or 11-R/00-R/00-RB (With adaptor) |

| Dies | 12-R |

| Usage/Applications | Heavy-Duty/Mech/ Elect Contractor/ Maintenance |

| Certifications/Approvals | UL/CSA/RoHS/WEEE |

Check out this informative video by RIDGID on how to use this pipe threader.

The RIDGID 700 Power Drive is the go-to choice for hand-held power drives, renowned for its exceptional power, robustness, and versatility. With a rugged cast aluminum housing, it is designed for heavy-duty applications, making it a reliable companion for everyday use.

Ideal for mechanical, electrical, and plumbing contractors, it effortlessly cuts both right and left-hand threads in seconds, saving time and effort.

It accommodates various applications with a pipe capacity of 1/8" to 2" (3mm-50mm). And if you have the right accessories, you can drive 12-R Die Heads, thread bolts from 1/4" to 1", and power 141 and 161 Geared Threaders for increased pipe capacity of 2 1/2" to 6", depending on if you buy just the tool (41935) or the kit (45178). With its reversible 115V universal motor, the RIDGID 700 Power Drive delivers reliable performance and durability.

RIDGID Model 700 Threader (Tool Only)

The RIDGID 41935 700 Power Drive Pipe Threader model is a standalone tool that is specifically designed for pipe threading. Unlike the RIDGID 45178, this model does not come included with dies, die heads, or other accessories.

Note

This version is significantly more affordable if you already have the accessories.

While the RIDGID 41935 Pipe Threader may require separate purchases of dies, die heads, and other accessories. It also offers flexibility for users to customize their threading setup according to their specific needs.

This makes it an ideal choice for professionals who already possess compatible dies and accessories or prefer to select them separately based on their individual requirements.

What’s in the RIDGID 41935 box:

- 700 Power Drive 115v Pipe Threader

RIDGID Model 700 Threader (Kit)

The RIDGID 45178 Power Drive Pipe Threader is a comprehensive package that includes the power drive itself and a range of essential accessories. This model comes equipped with 9 different components.

Check out this helpful video from RIDGID on how to remove die heads from the power drive.

In addition to the power drive and die heads, the RIDGID 45178 package includes the 42625 Arm Support 775, which provides stability and assists in handling the power drive during operation. The 42950 Metal Case ensures convenient storage and transportation of the entire set, keeping everything organized and protected.

Pro-Tip

If you don’t have the arm support with you, use a pipe wrench instead.

By opting for the RIDGID 45178 Power Drive Pipe Threader, users gain a comprehensive threading solution with all the necessary components included.

What’s in the RIDGID 45178 box

- (1) 41935 700 PD 115V

- (1) 37390 Diehead, CMPL 12R 1/2 NPT

- (1) 37395 Diehead, CMPL 12R 3/4 NPT

- (1) 37400 Diehead, CMPL 12R 1" NPT

- (1) 37405 Diehead, CMPL 12R 1-1/4 NPT

- (1) 37410 Diehead, CMPL 12R 1-1/2 NPT

- (1) 37415 Diehead, CMPL 12R 2" NPT

- (1) 42625 Arm, Support 775

- (1) 42950 case, metal 700

Applications for the RIDGID Model 700 Threader

Handheld power drives are perfect for low-volume applications, making threading pipes faster and easier. Unlike manual ratcheting threaders, these tools use a power drive to spin the die head around the pipe effortlessly, saving you time and physical effort.

Applications for the RIDGID 700 Power Drive Pipe Threaders:

- Plumbing installations and repairs: The RIDGID 700 Power Drive Kit is an adaptable tool for threading pipes in plumbing systems, making it ideal for residential and commercial plumbing installations and repairs. It enables precise and secure connections, ensuring leak-free plumbing systems.

- Electrical conduit threading: Electricians can benefit from the RIDGID 700 Power Drive Kit for threading electrical conduits. This ensures proper fitting of electrical wires and cables fitting within conduit systems, maintaining electrical integrity and safety.

- Pipe fabrication and maintenance: In various industries, including manufacturing, fabrication, and maintenance, the RIDGID 700 Power Drive Kit is essential for threading pipes during pipe fabrication and maintenance. It allows for the creation of customized pipe lengths and secure connections in a range of applications.

- Industrial piping projects: Industrial piping systems, such as those used in oil refineries, chemical plants, and power generation facilities, rely on threaded connections for reliable fluid transportation. Since the RIDGID 700 is portable, professionals can easily tackle any problem in these facilities.

- Mechanical contracting: Mechanical contractors involved in various projects, including HVAC installations, fire protection systems, and equipment maintenance, rely on the RIDGID 700 Power Drive Kit for threading pipes.

- Maintenance and repair work: The 700 Power Drive Kit is an indispensable tool for maintenance and repair work across various industries. Whether fixing plumbing systems, repairing pipelines, or addressing HVAC issues, this kit allows for efficient and precise pipe threading, saving time and effort.

RIDGID 700 Threader Accessories

With the utilization of different die heads, the RIDGID 700 Power Drive Pipe Threaders accommodate a range of pipe sizes and meet various threading requirements.

The RIDGID 37390 12R 1/2" NPT Die Head Complete is specifically designed for 1/2" NPT (National Pipe Thread) pipes. It enables the power drive to cut precise threads on the pipe ends, ensuring a secure and leak-free connection. Similarly, the RIDGID 37395 12R 3/4" NPT Die Head Complete is used for 3/4" NPT pipes, providing efficient threading capabilities.

For larger pipes, the RIDGID 37400 12-R Alloy Complete Diehead Manual Right Hand Threader is employed. This die head is designed for 1" NPT pipes and facilitates the threading process with its manual right-hand threading mechanism. Likewise, the RIDGID 37405 12R 1-1/4" NPT Die Head Complete is utilized for threading 1-1/4" NPT pipes.

These die heads, in combination with the RIDGID 700 Power Drive Pipe Threaders, ensure precise and reliable threading operations. They allow professionals to create strong and secure pipe connections, meeting the specific requirements of different pipe sizes and applications.

Pro-Tip

Die heads are vital components that ensure accurate and reliable threading for various pipe sizes and applications..

Furthermore, incorporating the RIDGID 10883 Oiler with 1 gallon of Nu-Clear Thread Cutting Oil makes the threading process even more efficient, with improved cooling, lubrication, and chip removal, resulting in enhanced performance and longevity.

Pro-Tip

According to Plumbermag.com, “An extreme amount of heat is created at the surface of the dies and, if not properly cooled, can lead to damage of the threads or the dies. Quality threading oils are produced with several additives that activate at various temperatures during the threading process to optimize cooling and lubricating. So it is important to frequently apply oil while producing the thread to maintain lubricity and flush the chips away from the dies.”

Seamless Threading, Anywhere

Pipe threaders, such as the RIDGID 700 Power Drive Pipe Threaders, offer a highly recommended approach for repairing plumbing pipes and working in smaller locations.

These versatile tools play a vital role in cutting precise threads on both male and female pipe ends, finding applications in various industries. The RIDGID 700 Power Drive Pipe Threader models stand out as cost-effective solutions that deliver exceptional performance and portability. With their mobility and precision, they streamline workflow and tackle demanding projects effortlessly.

The evolution of RIDGID Power Drives has revolutionized the pipe threading industry, with the Model 700 remaining a reliable workhorse.

By choosing the right pipe threader, professionals can enhance the efficiency of their projects and achieve seamless connections. With the extensive range of accessories available, including die heads for different pipe sizes like the RIDGID 37390, 37395, 37400, and 37405, the RIDGID 700 Power Drive Pipe Threaders accommodate various threading requirements and ensure precise and reliable results.

RIDGID 700 Hand-Held Power Drive Pipe Threader Frequently Asked Questions:

How much does a RIDGID 700 weigh?

This tool weighs roughly 25 pounds.

Which way should you turn a RIDGID 700 Pipe Threader?

You should make sure to turn it in a clockwise direction.

Should you wear gloves when operating this hand-held RIDGID 700 Pipe Threader?

No. Do not wear gloves or loose clothing when operating machines. Keep sleeves and jackets buttoned. Do not reach across the machine or pipe. Clothing can be caught by the pipe or machine, resulting in entanglement.

Is the RIDGID 700 Pipe Threader a handheld tool?

Yes, the RIDGID 700 Pipe Threader is a handheld tool, making it portable and convenient for on-site threading tasks.

Can the RIDGID 700 Pipe Threader be used for other applications?

Yes. The RIDGID Model 700 Power Drive can also be used in other applications such as to power the RIDGID 258 Pipe Cutter and to turn valves. These applications require the use of the No. 774 Square Drive Adapter.

How can I register my RIDGID 700 Pipe Threader for the LifeTime Service Agreement?

Check out our Comprehensive Guide to the RIDGID Lifetime Service Agreement for in-depth details and steps on how to register your RIDGID tool