Table of contents

RIDGID 1224 Pipe Threader: The Ultimate Threading Solution

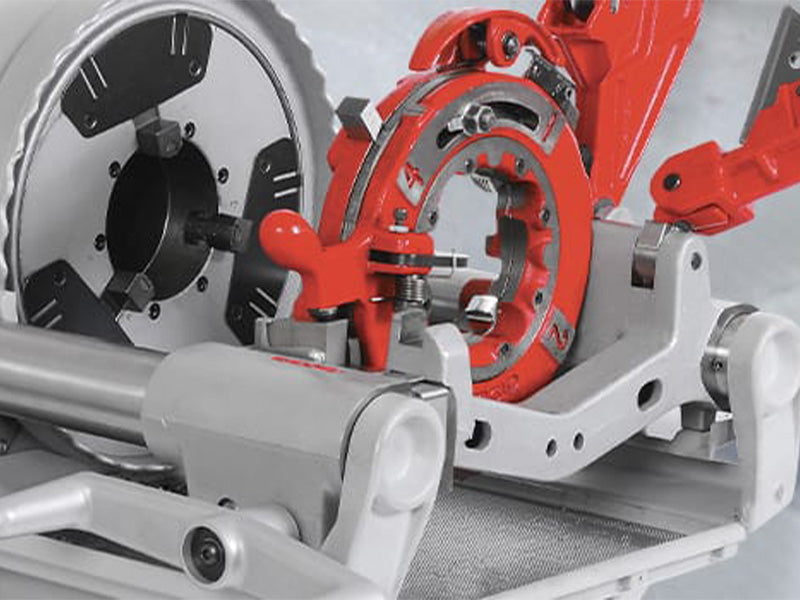

Let's talk about the RIDGID 26092 Model 1224 Pipe Threading Machine. If you're in need of a dependable, low-noise, and efficient solution for threading pipes, this machine has got you covered.

Whether you're working with black, galvanized, plastic-coated pipe, stainless steel, IMC, heavy-wall conduit, or rods up to 30 Rockwell C, this machine can handle them all. It features a special capacitor-start/capacitor-run motor, allowing it to thread various materials even when a voltage drop occurs.

The RIDGID 26092 Model 1224 Pipe Threading Machine is equipped with a 1/4"-2" universal die head and a 2-1/2" to 4" receding die head for cutting tapered or straight NPT/NPSM or BSPT/BSPP threads.

And guess what? You won't have to worry about lubrication - the 1224 constantly lubricates the dies and workpiece via its through-head oiling system.

Check out this quick overview of the RIDGID 26092:

So, if you're looking for a versatile, reliable, minimally noisy, and efficient pipe threading machine, the RIDGID 26092 Model 1224 is a great choice. It's built to handle diverse threading tasks and provide smooth and precise results. Get ready to boost your productivity and take your pipe threading game to the next level.

From Innovation to Industry Standard: The Remarkable Development of RIDGID Pipe Threader 1224

The RIDGID 1224 Pipe Threading Machine has a rich history. It all began in 1948 with the RIDGID 400 Handheld Pipe Threading Machine, a game-changing solution that revolutionized the pipe threading process and significantly impacted the industry. This innovation combined an electric motor with a geared scroll chuck, providing a portable and compact option for on-site applications.

In the '80s and '90s, RIDGID continued to bring further advancements in threading technology. One notable development during this time was the introduction of the lightweight Model 600 Power Drive. This Power Drive, known for its portability and versatility, further expanded the options available to professionals in the pipe threading industry. It provided a compact and lightweight solution for pipe threading, enabling tradespeople to tackle a wide range of projects easily.

RIDGID's introduction of the Model 600 Power Drive set the stage for further advancements, including the highly popular RIDGID 26092 Model 1224 Pipe Threading Machine. With its 1/4"-4" capacity, the Model 1224 became a pipe threading industry staple, demonstrating its versatility and precision in threading pipes of various sizes.

The enduring popularity of the Model 1224 within RIDGID's threading range is a testament to its ability to meet the evolving needs of industry professionals. Even as new technologies emerge, this machine remains a trusted solution due to its reliability and capability to deliver top-quality results.

Throughout its history, the RIDGID 1224 Pipe Threading Machine has played a central role in advancing threading technology. Its enduring presence reflects RIDGID's commitment to providing skilled tradespeople worldwide with reliable and durable solutions. Over 30 years, the Model 1224 has solidified RIDGID's reputation as an industry leader in threading technology.

RIDGID 26092 Model 1224 Package: Features, Specifications, and More

The RIDGID 26092 Pipe Threading Machine is equipped with impressive features. It can thread various pipes, including black, galvanized, plastic-coated, stainless steel, IMC, heavy-wall conduit, and rods up to 30 Rockwell C.

Accompanying this threading machine are essential tools and accessories. It accepts a large range of dies, including universal and receding dies, allowing you to cut tapered or straight NPT/NPSM or BSPT/BSPP threads. The package includes a wheel-type cutter, blade-type reamer, hex keys, a combination wrench, and Nu-Clear Thread Cutting Oil for smooth operation.

The RIDGID 26092 comprehensive package ensures you have everything at your fingertips for seamless pipe threading. Let's explore the convenience and efficiency this kit brings to the job site.

If you’re interested in how to use the RIDGID 1224 Threading Machine, watch this video.

What Comes With the RIDGID 26092 Package

- (1) Threading Machine

- 26132 - 711 SO Universal Right-Hand Dies

- 26152 - 714 SO Receding Right-Hand Dies

- 26192 - Dies. 1224 2 - 1/2" - 4 NPT HS

- 47745 - 1/2" - 3/4" Universal Alloy Die Set

- 47750 - 1" - 2" Universal Alloy Die Set

- 26212 - 1/4"-4" Wheel-Type Cutter

- 26217 - 1/4"-4" Blade-Type Reamer

- 33125 - Wheel, Cutter F229 3 & 4 HD

- 46030 - 3/16" Hex Key

- 46040 - Key, Hex 7/32

- 46190 - Hex Key, 1/4"

- 70835 - Nu-Clear Thread Cutting Oil

- 83975 - Wrench, 3/4 COMB

- 53693 - Tool Box

RIDGID 26092 Features

- Threads A Variety Of Pipes: Black, Galvanized, Plastic-Coated Pipe, Along With Stainless Steel, Imc & Heavy-Wall Conduit, And Rod Up To 30 Rockwell C

- Induction Motor: Helps to minimize noise.

- Special Capacitor-Start/Capacitor-Run Motor: This allows it to thread a full range of material where voltage drop is experienced

- 1/4"-2" Universal Die Head and 2-1/2" To 4" Receding Die Head allows cutting of tapered or straight Npt/Npsm Or Bspt/Bspp threads

RIDGID 26092 Benefits

- Speed: threads 1/4" – 2" pipe at 36 RPM and 2 1/2" – 4" at 12 RPM.

- Versatility: threads black, galvanized and plastic coated pipe, stainless steel, IMC, heavy-wall conduit, and rod up to RC 30.

- Low Voltage Operation: special start/run capacitors allow operation in less-than-ideal conditions.

- Quiet Operation: an induction motor insures sound levels are well within the limits OSHA sets.

Important According to OSHA, “employers [must] implement a hearing conservation program when noise exposure is at or above 85 decibels averaged over 8 working hours, or an 8-hour time-weighted average (TWA).”

RIDGID 26092 Specifications

| Pipe Capacity | 1/4"-4" (6mm-100mm) 4"-6" (100mm-150mm) with 161 Geared Threader |

| Bolt Capacity | 1/4"-2" (6mm-50mm) |

| Motor | 1-1/2 HP, single-phase, 60 Hz, induction type |

| Motor Control | Reverse/Off/Forward, heavy-duty rotary-type and integral foot switch |

| Spindle Speed | 36/12 RPM |

| Gear Box | Two-speed gearbox |

| Chuck | Hammer-type with replaceable rocker-action jaw inserts |

| Rear Centering Device | Cam action |

| Cutter | Model 764 full-floating, self-centering 1/4"-4" with F-229 cutter wheel |

| Reamer | Model 744, 1/4"-4" blade-type |

| Pump | Self-priming, gerotor-type, automatic-reversing, constant-flow |

Quick Facts:

- Induction Motor: Helps to minimize noise

- Pipe Capacity: 1/4"-4" (6mm-100mm) 4"-6" (100mm-150mm) with 161 Geared Threader

- Bolt Capacity: 1/4"-2" (6mm-50mm)

- Motor: 1-1/2 HP, single-phase, 60 Hz, induction type

- Spindle Speed: 36/12 RPM

- Threads A Variety Of Pipes: Black, Galvanized, Plastic-Coated Pipe, Along With Stainless Steel, Imc & Heavy-Wall Conduit, And Rod Up To 30 Rockwell C

What is an Induction Motor?

A single-phase induction motor is commonly used in various applications, including threading machines.

It operates on the principle of electromagnetic induction to generate rotational motion. Unlike three-phase motors, which require three power supply lines, a single-phase induction motor operates on a single-phase alternating current (AC) power supply.

Threading machines often utilize single-phase induction motors for their simplicity, cost-effectiveness, and reliability. These motors can deliver sufficient torque and power for the threading process while maintaining a compact size.

Additionally, single-phase motors are commonly found in residential and small-scale industrial settings, making them readily available and compatible with existing power infrastructure.

One notable advantage of a single-phase induction motor in a threading machine is its quiet operation. These motors typically feature sturdy construction and efficient design, which helps reduce noise and vibrations during operation. The inherent design characteristics, such as the absence of brushes or commutators, contribute to the motor's smooth and quiet performance.

As a result, the threading machine can be operated with minimal disturbance, providing a more comfortable working environment for the user and reducing overall noise pollution in the vicinity.

Exploring the Applications of the RIDGID Pipe Threader 1224: From Plumbing to Agricultural Projects

The RIDGID 1224 Pipe Threader is a versatile tool used in construction, HVAC, oil and gas, industrial maintenance, plumbing, and more. It ensures leak-free plumbing systems, efficient heating and cooling distribution, robust connections for fluid transportation, and precise threading in various applications.

Knowing and understanding the die adjustment for different pipe sizes is essential when working with many applications. Check out this video by RIDGID to better understand.

From construction projects to industrial maintenance, the RIDGID 1224 Pipe Threader delivers reliable and efficient pipe threading for professionals across different industries.

- Construction: The RIDGID 1224 Pipe Threader is widely used in construction projects for threading pipes used in plumbing systems, such as water supply lines, drainage systems, and gas lines. It is essential for creating secure and leak-free connections in residential, commercial, and industrial buildings.

- HVAC Systems: The 1224 Pipe Threader is utilized in HVAC (Heating, Ventilation, and Air Conditioning) installations for threading pipes that carry hot and cold water, refrigerant lines, and ductwork. It ensures precise and reliable connections, enabling efficient heating and cooling distribution throughout buildings.

- Oil and Gas Industry: In the oil and gas sector, the RIDGID 1224 Pipe Threader is employed for threading pipes that transport petroleum, natural gas, and other fluids. It plays a vital role in creating strong and durable connections that withstand high pressures and harsh environments, ensuring the safe and efficient flow of resources.

- Industrial Maintenance: The 1224 Pipe Threader finds applications in industrial maintenance tasks, including repairing and maintaining pipelines, machinery, and equipment. It enables workers to quickly thread pipes for various purposes, such as pneumatic systems, hydraulic lines, and process piping, ensuring uninterrupted operations and minimizing downtime.

- Plumbing Services: Professional plumbers use the RIDGID 1224 Pipe Threader to thread pipes during installations, repairs, and renovations. It is used for various plumbing applications, including water distribution, drain, sewer, and sprinkler systems. The threader ensures secure and reliable connections, preventing leaks and ensuring proper water flow.

- Municipal Infrastructure: The RIDGID 1224 Pipe Threader is indispensable in municipal infrastructure projects. It is used for threading pipes in water supply networks, sewer systems, stormwater management systems, and irrigation systems. This facilitates efficient water distribution and the proper functioning of municipal services.

- Mechanical Engineering: In mechanical engineering applications, the 1224 Pipe Threader is utilized for threading pipes in machinery, equipment, and mechanical systems. It enables the creation of precise connections for conveying fluids, gases, and lubricants, ensuring optimal performance and reliability of mechanical systems.

- Fire Protection Systems: The RIDGID 1224 Pipe Threader is employed in installing and maintaining fire protection systems, such as sprinkler systems and fire hydrants. It is used to thread pipes that carry water or fire suppression agents, ensuring the system's integrity and providing reliable fire safety measures.

- Manufacturing and Fabrication: The 1224 Pipe Threader is utilized in manufacturing and fabrication processes where threaded pipes are required. It is used for creating support structures, conveyance systems, and custom machinery. The threader ensures precise threading, allowing for the seamless integration of pipes into the manufacturing process.

- Agricultural Applications: The RIDGID 1224 Pipe Threader plays a role in agricultural applications, such as irrigation systems, water supply lines for livestock, and equipment maintenance. It enables the threading of pipes used in agricultural infrastructure, ensuring reliable water distribution and efficient farming operations.

RIDGID Pipe Threader 1224 Accessories

If you want to take your RIDGID 1224 Pipe Threader to the next level, consider adding these four popular optional accessories that can enhance its capabilities:

1. RIDGID 92467 200 universal wheel and cabinet stand for threaders:

This accessory comes with the 200 Universal Wheel and Cabinet Stand, providing a convenient and versatile solution for your threading machine. It is adjustable to fit 1822, 535, and 1224 Threading Machines.

The large diameter wheels make it easy to transport on the job site. With its sturdy 17 gauge steel walls and welded construction, you can rely on its durability. The cabinet stand features two internal and one external storage shelf, allowing you to organize your tools.

It also has an oversized bi-fold door with a steel clasp for secure closure. Plus, it includes cut-outs for the power cord and foot switch storage and two drain plugs for easy cleaning.

This accessory fits the 1822, 535, and 1224 Threading Machines. It features a heavy-duty steel frame that ensures maximum stability and rigidity during operation.

The large dent and corrosion-resistant tool tray offer added convenience by providing a dedicated space for your essential threading tools. You can easily transport the machine around the job site with its large-diameter wheels.

The RIDGID 51005 Nipple Chuck Kit is a valuable accessory for your threading machine. It allows you to hold short or closed nipples for threading securely and also holds studs for threading purposes. This kit is versatile and compatible with the 300 Power Drive, 300 Compact, 535 and 1822 (with adapter kit 35867), and 1224 Threading Machines. It includes a standard Nipple Chuck with an insert and five adapters: 1/2", 3/4", 1", 1-1/4", and 1-1/2". The Nipple Chuck body itself serves as a 2" Adapter, making it a comprehensive solution for your threading needs.

4. RIDGID 26192 high-speed pipe dies for 1224 threading machine, 2-1/2" - 4" NPT 4-PACK:

If you often work with larger pipe sizes, the RIDGID 26192 High-Speed Pipe Dies are a must-have accessory. This 4-pack of dies is designed for the 1224 Threading Machine and enables you to thread pipes ranging from 2-1/2" to 4" NPT. With these high-speed dies, you can efficiently and accurately thread larger pipes, expanding the capabilities of your threading machine.

Adding these optional accessories to your RIDGID 1224 Pipe Threader allows you to customize and optimize its performance to meet your specific threading needs.

Conclusion

The RIDGID 1224 Pipe Threader is a highly efficient and versatile tool for threading pipes. It is designed to handle various pipe sizes and materials precisely and quickly. Its powerful motor and through-head oiling system ensure reliable performance even in challenging conditions.

Trusted by construction, HVAC, plumbing, oil and gas professionals, the RIDGID 1224 has a proven innovation and reliability track record. It can significantly boost productivity and deliver professional-quality threading results. By adding optional accessories, its capabilities can be further enhanced, making it a reliable choice for various applications.

Overall, the RIDGID 1224 Pipe Threader is a dependable tool that offers efficiency and accuracy in pipe threading. Its versatility and reputation for reliability have made it a trusted choice among professionals in multiple industries. Its powerful motor and innovative features can handle various pipe sizes and materials, ensuring smooth and precise threading results.

Whether used in construction, HVAC, plumbing, or the oil and gas sector, the RIDGID 1224 delivers reliable performance, even in challenging conditions making it an excellent investment.

RIDGID 1224 Pipe Threader Frequently Asked Questions

How can I register my RIDGID 700 Pipe Threader for the Lifetime Service Agreement?

Check out our Comprehensive Guide to the RIDGID Lifetime Service Agreement for in-depth details and steps on how to register your RIDGID tool

What is the difference between light and dark cutting oil?

The selection between clear and dark cutting oil is contingent upon the rpm rating of your threading machine. To put it simply, dark-cutting oil is intended for high-speed machine threading, whereas clear-cutting oil is suitable for low-speed hand threading.

What is the recommended depth for tapping an NPT thread?

It is generally advised to tap an NPT thread to a depth of approximately 2/3rd of the thread length of the tap. To ensure accuracy, it is recommended to use a reliable gauge or obtain a mating thread from a trusted source. Using a hex socket pipe plug can help achieve 3 to 3-1/2 turns of engagement for proper threading.

What is the difference between NPT and MIP threads?

MIP stands for Male Iron Pipe, while NPT refers to National Pipe Thread, both of which indicate male fittings with NPT threads. Similarly, FPT represents Female Pipe Thread, and FIP represents Female Iron Pipe, denoting female fittings with NPT threads.

What are the two chucks on a pipe threading machine?

The first chuck, located nearest the die head, is commonly known as the chuck. In threaders, the majority of chucks are of the hammer type. The second chuck, positioned at the rear, serves as a centering chuck. It is important not to overtighten the centering chuck; instead, it should be adjusted until it lightly touches the material without excessive pressure.

Is Teflon tape necessary for pipe threads?

Plumber's tape is highly recommended for threaded connections without a built-in rubber seal. It serves multiple purposes: providing a lubricated surface for smoother threading, preventing pipes from sticking during disassembly, and enhancing the overall tightness of the joint.

How do I determine the correct die size for a specific pipe diameter?

A pipe thread sizing chart or a thread gauge can determine the correct die size for a specific pipe diameter. These tools provide guidance on selecting the appropriate die size based on the pipe's outer diameter and the desired thread type.