Table of contents

RIDGID 535 Pipe Threader: Comprehensive Model Review

Do you need a pipe threader that can boost your work productivity and allow for longer, uninterrupted threading sessions?

Well, I've got some good news for you!

Let's talk about the RIDGID Pipe Threader 535A and its two impressive models: the RIDGID 91142 535A Automatic Pipe Threader Machine Only and the RIDGID 84097 535A (Pipe 1/8 - 2") Automatic Threading Machine (2 Die Sets 1 Die Head Included).

If you want a threader that keeps the workflow going smoothly, the new Model 535A is the way to go. With its large chip tray and oil reservoir, you can say goodbye to constant interruptions during threading. The high clearance carriage makes the whole threading process a breeze, while the roomy top cover area keeps all your essential tools and materials at your fingertips.

So, if you're ready to take your pipe threading to the next level, join us as we explore these two models in-depth. We'll break down their features and advantages, giving you all the insights you need to make an informed decision.

Pipe Threading Pioneers: Charting the Evolution of RIDGID Pipe Threaders

Threading pipe gained popularity in the 1940s due to technological advancements, transforming it from a slow and tedious process to a valuable solution for various applications.

At RIDGID, threading has evolved, primarily serving industrial and commercial needs. The introduction of the RIDGID 400 Power Drive in 1948 revolutionized the industry by combining an electric motor, geared scroll chuck, and rear centering device for pipe manipulation.

Continuous development led to the Model 500, which became the industry standard for over four decades, thanks to innovations like the RIDGID Speedchuck that improved threading speed and grip on materials.

Today, the new 760 FXP Power Drive is a portable and efficient option, featuring precise threads, Brushless Motor Technology for reduced maintenance, and added safety measures such as automatic shut-off in case of severe kickback.

Building a Legacy: RIDGID Threading Machines at the Heart of Iconic UK Building Renovations

In the United Kingdom, RIDGID Threading machines played a crucial role in renovating iconic buildings.

At Buckingham Palace, these machines were used for sprinkler installation and re-piping throughout the entire structure. Windsor Castle benefited from ongoing repairs, including installing new boilers, made possible with the assistance of RIDGID Threading machines.

Wembley Stadium relies on these machines for essential piping work, ensuring the smooth operation of its facilities. Similarly, the House of Parliament utilizes RIDGID Threading machines for piping and sprinkler installations.

Beyond individual buildings, RIDGID Threading machines also contribute to larger infrastructure projects like the Great North Rail Project, Eurostar Crossrail Elisabeth Lane, HS2, and the replacement of the Victoria Sewage Line across the UK, supporting water treatment plant operations and maintaining critical services nationwide.

What is a RIDGID 535A Pipe Threader?

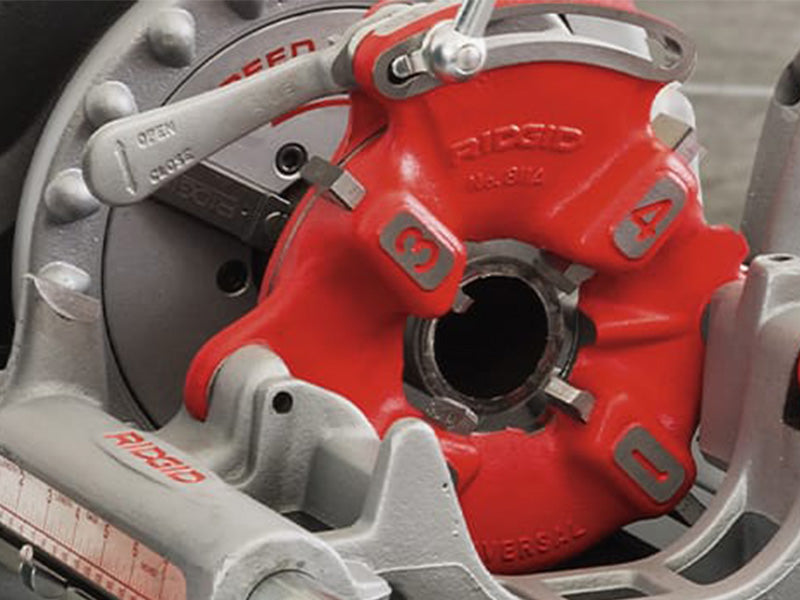

The RIDGID 535A pipe threader rotates a die around the pipe, gradually cutting precise grooves into the pipe's outer surface. These grooves form the threads that allow you to screw one pipe into another, creating a tight and secure joint. The RIDGID 535A offers automatic threading capabilities, ensuring a smooth operation.

The automatic chuck mode simplifies the process by feeding the pipe and cutting the threads consistently and accurately. This chuck saves you time and effort and ensures uniform and reliable results across multiple threaded connections.

Without an automatic chuck pipe threader, achieving proper and secure pipe connections can be time-consuming and challenging.

RIDGID 535A Pipe Threader Features and Key Differences

In this short and informative video, you'll get a firsthand look at the functionality of the RIDGID 353A automatic threading machine.

RIDGID 535A Pipe Threader Features

| Pipe Capacity | 1/8"-2" (3 mm-50 mm) 2 1/2"-4" (62 mm-100 mm) with 141 geared threader |

| Bolt Capacity | 1/4"-2” (8 mm-50 mm) |

| Switches | Forward/off/reverse and integral safety foot switch |

| Chuck | Automatic with four reversible forged jaws |

| Rear Centering Device | Automatic, centering only |

| Cutters | Self-centering, full-floating. |

|

|

| Reamer | 5-flute cone, RH, 1/8"-2" (3 mm-50 mm) |

| Oil Pump | Self-priming gerotor oil pump |

Note

RH/LH combination reamer is available

Key Differences:

The key differences between the RIDGID 91142 535A Automatic Pipe Threader Machine and the RIDGID 84097 535A Automatic Threading Machine with 2 die sets and 1 die head included are as follows:

Threader Machine Package:

- The RIDGID 91142 package only includes the automatic pipe threader machine without additional accessories or die sets.

- The RIDGID 84097 package includes the automatic threading machine along with 2 die sets, and 1 die head. This package provides users with a more comprehensive solution right out of the box.

Cost Considerations:

- The RIDGID 91142 535A, the machine-only option, generally has a lower upfront cost than the RIDGID 84097 535A, which includes additional accessories.

- The RIDGID 84097 535A, with its included die sets and die head, may provide long-term cost savings since users don't need to purchase these components separately.

RIDGID Model 535A Threader (Tool Only)

The RIDGID 91142 Power Drive Pipe Threader is a versatile tool designed specifically for pipe threading applications. Unlike the RIDGID 84097 model, which comes bundled with dies, die heads, and other accessories, the 91142 model is a standalone unit.

NOTE

This version is significantly more affordable if you already have the accessories.

Despite not including additional components, the RIDGID 91142 Power Drive Pipe Threader maintains its counterpart's exceptional quality, features, and capabilities.

It boasts a robust construction and a reliable motor that contribute to its ability to withstand challenging job site conditions. Moreover, it is equipped with a generous chip tray and oil reservoir, enabling extended threading sessions without interruptions and minimizing downtime.

While the RIDGID 91142 Pipe Threader may require separate purchases of dies, die heads, and other accessories. It also allows users to customize their threading setup according to their needs.

This machine-only option makes it ideal for professionals with compatible dies and accessories or who prefer to buy them separately based on their requirements.

What’s in the RIDGID 91142 Box:

- (1) No. 341 Reamer

- (1) No. 820 cutter

- (1) gallon stainless steel premium oil

- (2) hex wrenches

- (1) spare E-1032 cutter wheel

RIDGID Model 535A Threader (Set)

The RIDGID 84097 535A Automatic Threading Machine is a powerful and versatile tool designed to streamline the pipe threading process.

With its automatic threading feature, this machine takes the hassle out of creating precise threads on pipes. It includes two die sets and one die head, providing flexibility to work with various pipe sizes ranging from 1/8 to 2 inches.

The 84097 535A also offers a large chip tray and oil reservoir, ensuring longer uninterrupted threading sessions and reducing downtime. This threading machine is built with the needs of professionals in mind, offering efficiency, convenience, and reliability for a wide range of pipe threading applications.

Pro-Tip

By opting for the RIDGID 84097 Power Drive Pipe Threader, users gain a comprehensive threading solution with all the necessary components included.

What’s in the RIDGID 84097 Box:

- (1) No. 811A Universal, Quick-opening Die Head (for models 816/817 die heads) sold separately

- (1) No. 341 Reamer.

- (1) No. 820 Cutter.

- (1) Set 1/2"-3/4" Universal High-Speed Dies.

- (1) Set 1" - 2" Universal High-Speed Dies.

- (1) Gallon Stainless Steel Premium Oil.

- (2) Hex Wrenches.

- (1) Spare E-1032 Cutter Wheel.

Pro-Tip

Stand Not Included

Applications for the Model 535A Threader

Are you interested in seeing how the RIDGID 535A works in detail? Watch this instructional video.

The 84097 535A offers automatic threading capabilities, two die sets, and a die head, allowing for versatility in threading pipe sizes ranging from 1/8 to 2 inches. On the other hand, the 91142 535A is a machine-only option that provides efficient automatic pipe threading while letting professionals customize their dies. Both machines find applications in plumbing, construction, and industrial projects, offering reliable performance and precision.

Let's explore the possibilities and applications of these two products.

- Construction projects: It is suitable for threading pipes used in construction applications, such as HVAC installations, water supply lines, and drainage systems.

- Industrial maintenance and repairs: The RIDGID 535A is handy for industrial maintenance tasks, including repairing or replacing threaded pipes in manufacturing facilities, warehouses, or production lines.

- Oil and gas industry: This threading machine can be used in the oil and gas sector for threading pipes used in pipelines, refineries, and petrochemical plants.

- Municipal projects: It is suitable for threading pipes in infrastructure projects like water treatment plants, sewage systems, and utility networks.

- Plumbing services: Plumbing professionals commonly use the RIDGID 535A pipe threaders for threading pipes in residential, commercial, and industrial plumbing projects.

- Pipe fabrication: It is a valuable tool for pipe fabricators who must create threads on pipes used in various applications, such as structural supports, machinery, or equipment.

- Mechanical and engineering applications: The 535A is utilized in mechanical and engineering projects where threaded pipes are required for mechanical systems, machinery, or equipment connections.

- Irrigation systems: They can be used in the installation and maintenance of irrigation systems, ensuring secure connections between pipes, valves, and sprinkler heads.

As mentioned in market research data, “Pipe threading machines are also employed in the installations of water and sewage systems, which are essential in urban areas. Hence, rise in urban population and expansion in oil & gas sector are augmenting the pipe threading machine market development.”

Regarding pipe threading applications, both the RIDGID 84097 535A Automatic Threading Machine and the RIDGID 91142 535A Automatic Pipe Threader Machine are powerful machines highly valued in several industries.

The RIDGID 84097 535A is a remarkably versatile machine equipped with two die sets and a die head. This feature allows it to handle a wide range of pipe sizes, making it suitable for various applications in plumbing, construction, and industrial projects.

In contrast, the RIDGID 91142 535A also provides efficient automatic threading but does not come bundled with die sets or die heads. This model makes it a dedicated machine designed for professionals with the necessary accessories or who prefer to customize their toolset. It offers the same level of reliability and efficiency as its counterpart, making it a reliable choice for plumbing installations, construction projects, or industrial maintenance tasks.

Growth in the Pipe Threading Industry

According to a market study on pipe threading machines, the industry is witnessing steady growth driven by infrastructure development, urbanization, and industrial expansion. The demand for pipe threading machines is expected to continue rising in the foreseeable future.

Manufacturers are focusing on developing advanced threading machines with features like automatic threading, improved efficiency, and enhanced precision. These technological advancements cater to construction, plumbing, and manufacturing professionals who rely heavily on pipe threading operations.

One notable trend in the market is the increasing adoption of electric and hydraulic pipe threading machines. These machines offer advantages such as reduced noise, increased productivity, and easier operation. This shift towards electric and hydraulic models reflects the industry's pursuit of more efficient and user-friendly solutions.

Overall, the pipe threading machine market is characterized by ongoing innovation and a growing preference for advanced models. Professionals in various industries can expect improved efficiency and productivity as manufacturers continue to introduce cutting-edge features and technologies to meet the evolving demands of the market.

RIDGID 535A Threader Accessories

Enhancing the performance of the RIDGID 535A Threader are a few notable accessories. The RIDGID 47770 Universal Dies High-Speed stands out for its precision and efficient pipe threading capabilities. These high-speed universal dies enable smooth and rapid cutting, saving valuable time during threading tasks. With a size range of 1" to 2", they cover common pipe diameters, making them versatile for various applications.

Regarding lubrication, the RIDGID 10883 Oiler with 1-gallon Nu-Clear thread-cutting oil is essential. This oiler provides a consistent flow of cutting oil, ensuring proper lubrication for the threading process. The 1-gallon capacity allows for extended usage without frequent refills, while the high-quality Nu-Clear oil enhances cutting efficiency and prolongs the lifespan of the dies and the RIDGID 535A Threader.

Pro-Tip

Here are some key reasons why thread-cutting oil is essential:

• Cools threads and pipe during operation.

• Speeds up the metal removal process.

• Enhances the thread quality.

• Reduces the threading torque.

Another valuable accessory is the RIDGID 47765 Universal Dies. These dies are designed for smaller pipe diameters and are compatible with the RIDGID 535A Threader. With a size range of 1/2" to 3/4", they cover commonly used pipe sizes in plumbing and construction applications. These dies increase efficiency and accuracy, allowing for quick and precise cutting.

In summary, the RIDGID 535A Threader accessories, including the RIDGID 47770 Universal Dies High-Speed, RIDGID 10883 Oiler with 1-gallon Nu-Clear thread cutting oil, and RIDGID 47765 Universal Dies High-Speed, play crucial roles in optimizing the threading process.

These accessories enhance efficiency, precision, and longevity, making professionals' pipe threading tasks more accessible and practical.

Sealing the Deal

The RIDGID 535A pipe threader is a powerful machine revolutionizes the pipe threading process. It offers automatic threading capabilities, ensuring smooth and efficient operations. Its large chip tray, oil reservoir, and high clearance carriage eliminates interruptions and simplifies threading tasks.

This comprehensive review explored two models: the RIDGID 91142 535A Automatic Pipe Threader Machine Only and the RIDGID 84097 535A Automatic Threading Machine with 2 Die Sets and 1 Die Head Included. These machines have their differences, with the 91142 being a standalone unit and the 84097 offering an overall solution with additional accessories.

The versatility of both models makes them ideal for a wide range of applications, including construction, plumbing, industrial maintenance, and more. As the pipe threading industry expands due to infrastructure development and urbanization, the demand for reliable threading machines is projected to keep rising. To stay ahead of the curve, enhance your pipe threading capabilities with the RIDGID 535A and experience boosted productivity and seamless threading sessions.

RIDGID 535A Pipe Threader Frequently Asked Questions:

How much oil does a RIDGID 535A pipe threader hold?

1.75 gallon

What is the difference between a 535A Automatic Rigid threader and a 535A Rigid Power threader?

The 535A has a speed chuck with three replaceable rocker-action jaw inserts, while the 535A has an automatic chuck with four reversible forged jaws.

What are the minimum pipe thread sizes for the RIDGID 535A?

Pipe Capacity 1/8"-2" (3 mm-50 mm) 2 1/2"-4" (62 mm-100 mm) with 141 geared threader.

What is the power source for the RIDGID 535A Pipe Threader?

The RIDGID 535A Pipe Threader is powered by an electric motor, ensuring consistent and reliable performance during pipe threading operations.

How often should the cutting oil be replenished in the RIDGID 535A Pipe Threader?

The RIDGID 535A Pipe Threader cutting oil should be replenished regularly to ensure proper lubrication and optimal threading performance. The frequency of oil replenishment may vary depending on the extent of use.