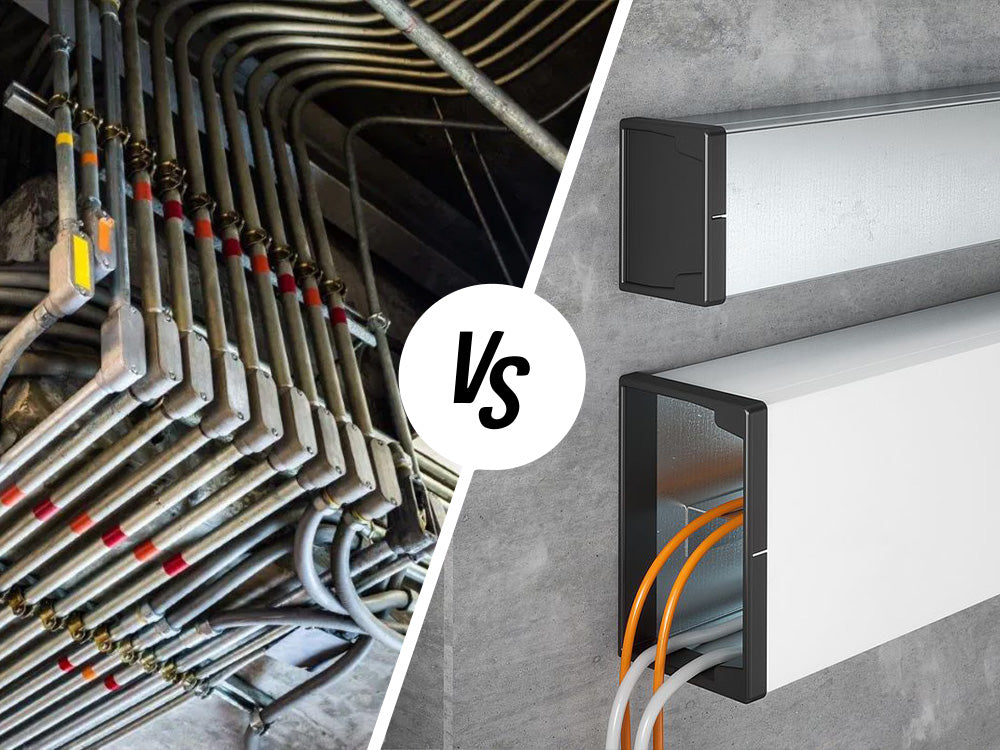

Trunking vs Conduit: What’s the Difference?

In electrical work, making sure that your wiring and cables are secure, organized, and safe is the highest priority. Both trunking and conduit systems do more than just keep the cables organized. They also protect them from damage from outside sources while keeping your electrical setup neat and running efficiently. Whether you’re wiring a home or business, poor cable management will lead to potential hazards in the long run.

Choosing the right cable organizational containment system, like either Trunking or Conduit, is the two most popular choices; you need to consider factors such as the visibility of the cables, the material needed to keep wires from eroding, and compatibility with the building structure. Understanding what fits your system is important because the wrong one could cause damage, and even though Trunking and Conduit are often used interchangeably when talking about electrical wiring, they have a variety of differences.

Explore the differences between trunking and conduit, and learn about what they are, their key differences, and the pros and cons of each. Decide on which cable wire organizational system to use to keep your cables organized, safe, and protected.

For a quick look at what conduits and trunking look like, take a look at this quick video explanation from Preston College TV.

What is Conduit?

To put it simply, conduit is a type of protective tubing often used to enclose and safeguard electrical wiring from physical damage, moisture, and other environmental hazards in installations. Conduit provides a solid and sturdy path for electrical cables to pass through, making sure that it remains intact and protected over time. It’s commonly used in both commercial and industrial installations, along with residential jobs, if it requires an added warning of potential outdoor exposure or a need for more durability.

Types of Conduit

Rigid Metal Conduit (RMC), Electrical Metallic Tubing (EMT), and PVC conduit each serve specific purposes based on the environment they’re being used it and their application. Each type of conduit provides benefits that cater to different wiring needs, ensuring that wiring systems remain secure and functional in a variety of environments.

Rigid Metal Conduit (RMC)

If you need a heavy-duty option, RMC is the one to choose. It’s made from galvanized steel to provide maximum protection even in the harshest environments. This conduit is ideal for outdoor installations, especially in industrial settings where, most often, there tends to be a lot of work happening and impact resistance is a requirement. Overall, RMC tends to be tough, bulky, and built to withstand almost everything that gets thrown at it.

Electrical Metallic Tubing (EMT)

If you need a more lightweight, thinner option compared to RMC, check out EMT, which is often referred to by professionals as a “thin-wall” conduit. EMT is made from coated steel or aluminum making it easier to work with due to its flexibility. You’d most often use EMTs indoors in commercial buildings, providing protection without the added weight and cost of RMC.

PVC Conduit

PVC conduit, on the other hand, is different from both RMC and EMC because it’s made from plastic. Though not made from steel, it’s known for its corrosion resistance because it doesn’t rust like its metal counterparts. PVC is ideal for underground installations or areas where it’ll be exposed to water frequently. Not only does it not rust, but it’s also non-conductive, adding an extra layer to electrical setups. Overall, PVC is lightweight and affordable for residential and light commercial applications.

Uses of Conduit

- Protection from Physical Damage: Conduit acts as a shield for electrical wiring, protecting it from being cut, crushed, step-on, or otherwise damaged. Whether the wires are running through a wall, underground, or out in the open, conduit keeps them safe from harm and humans safe from them.

- Outdoor/Industrial Applications: Conduit is a favorite for outdoor or industrial environments, where cables might face exposure to the elements or heavy machinery. Its durability ensures that the wiring stays secure, even in rough conditions like extreme temperatures, moisture, or UV exposure.

- High Durability for Rugged Environments: For installations in places like factories, construction sites, or other heavy-duty environments, conduit provides the toughness required to keep wiring systems functional and safe. Conduits like RMC, EMC, and PVC can handle harsh environments and are able to offer long-term protection against wear and tear, corrosion, and impact.

What is Trunking?

Trunking is another type of cable management that is designed to organize and protect electrical wires. It’s made to keep electrical wires out of the way by providing an accessible way to run cables across walls, ceilings, and floors.

Unlike conduit, which is a fully enclosed system, trunking instead is an open channel that provides electricians and other maintenance professionals with an easier way to access and manage cables after installation. For jobs that may require frequent changes or additions to the wiring like in offices, commercial spaces, or even residential areas, trunking would be the go-to solution. Trunking not only protects cables but also improves the overall appearance of wiring by keeping it hidden and organized together.

Types of Trunking

Just like Conduit, trunking has specific cable management needs. For basic, affordable setups, you’ll want something lightweight, easy to install, and resistant to corrosion, ideal for everyday residential or commercial use. In more demanding environments like industrial or construction sites, durability, fire resistance, and impact protection are top priorities, requiring heavy-duty materials to keep cables safe. If electromagnetic interference is a concern on the jobsite, systems that offer proper shielding and earthing are needed to protect against interference. In smaller spaces, a compact solution is often necessary to keep cables hidden and organized without taking up much room.

Each type of trunking addresses these needs differently and effectively.

PVC Trunking

The most common type of trunking is PVC trunking. It’s popular because of its affordability, ease of installation, and corrosion resistance. PVC trunking is set up to be flexible and lightweight making it easy to both maneuver and easily cut to fit your needs. For residential and commercial settings, PVC trunking is also widely used because of its aesthetic appeal and professional look by cleaning up the wires from out in the open. Plus, it's available in various sizes.

Steel Trunking

Steel trunking similar to RMC and EMC conduits is made for more robust environments, especially in places where fire or heavy-duty durability is a potential hazard. Made from galvanized steel, this type of trunking can be seen in industrial settings or where extra protection is needed from frequent impacts or other harsh conditions. It provides the strength of metal while maintaining the accessibility that trunking is known for. Steel trunking is the choice when protection and longevity is important.

EMC Trunking

For installations that deal with electromagnetic compatibility, EMC trunking is used to protect against interference while ensuring proper grounding. By using dedicated EMC cables, glands, and shielding, this type of trunking helps to minimize electromagnetic radiation and reduces the risk of short circuits.

When you’re working with high-current cabling, using a trunking system that is designed for electrical applications is important to make sure that there is effective screening and protection.

Bus-Bar Trunking

Bus-bar trunking systems are designed to distribute electrical power efficiently and safely. These systems use a series of metal bars housed within a protective enclosure to carry high electrical currents. They offer a compact and reliable solution for distributing power in commercial and industrial environments. Their modular design allows for easy installation and expansion, making them suitable for buildings with evolving power needs.

Multi-Compartment Trunking

Multi-compartment trunking provides an organized way to manage and separate multiple types of cables within a single trunking system. Each compartment is dedicated to a specific type of wiring—such as power, data, or communication cables—allowing for neat and efficient cable management. This system reduces the risk of interference between different cable types and simplifies maintenance and future upgrades by keeping everything in its designated space.

Mini Trunking

Mini trunking is a smaller, more compact version of traditional trunking designed for discreet cable management in tight spaces. It’s commonly used in homes or small offices where the wiring needs to be hidden but doesn’t require a large, bulky system. Mini trunking is great for running cables along baseboards, under desks, or behind furniture, offering a low-profile solution that keeps things tidy without taking up much space.

Uses of Trunking

- Indoor Applications: Trunking is mainly used indoors because it helps to keep wiring both clean and organized. Whether it’s an office or a commercial building, trunking makes sure that cables and wires are kept out of sight and out of mind while remaining accessible to technicians.

- Easier Cable Access and Expansion: Trunking’s main advantage is that it allows for easy cable access even after installation. If you need to add more wiring, make repairs, or reroute cables, trunking makes it simple—just pop open the channel, fix or replace the wires, and close it back up. This flexibility is a significant reason why it’s preferred in environments where systems need regular maintenance or adjustments.

Trunking is all about convenience and adaptability, perfect for installations that may require changes. It offers a flexible, organized, and visually clean way to manage cables, especially in indoor environments.

Key Differences Between Conduit and Trunking

The factors to consider when choosing between conduit and trunking for electrical installations include installation steps, cost, durability, and flexibility.

Conduit, on the one hand, takes more time and skillset to install because it tends to involve more strenuous work through cutting, bending, and specialized tools, while trunking offers professionals a quicker, cut-to-fit approach that needs few tools to get the job done, making it great for projects that are finishing quickly.

When it comes to costs, conduit tends to be on the more expensive side due to the overall material costs and labor that go into installation, whereas trunking is the more budget-friendly option with lower material costs and less labor-intensive installation because of its openness.

In terms of durability and ruggedness, conduit is what’s commonly used for harsh environments because it’s able to provide advanced protection against physical damage, moisture, and fire. Trunking, on the other hand, is best suited for indoor environments like offices or homes out of the elements because it’s not fully enclosed to provide easy access to professionals.

Lastly, flexibility on jobs is important to be aware of because, depending on the project, you may need more ways to manipulate the protection for wires.

Trunking offers more flexibility and easier access for future modifications or cable additions. At the same time, conduit can be harder to modify once installed, making it less ideal for environments where frequent wiring changes can happen.

Quick Facts: Trunking Vs Conduit

Installation

Conduit:

Requires cutting and bending

More time-consuming installation

Needs specialized tools and skilled labor

Trunking:

Simple cut-and-fit installation

Quick to install, minimal tools needed

Ideal for fast projects or minimal disruption

Cost

Conduit:

Higher cost due to materials (especially metal conduits like RMC and EMT)

Labor-intensive, leading to increased installation costs

Trunking:

More budget-friendly

Lower material costs, especially with PVC

Less labor-intensive, saving on time and money

Durability

Conduit:

Extremely durable, ideal for harsh environments

Provides strong protection from physical damage, moisture, and fire

Suitable for industrial, outdoor, or high-impact areas

Trunking:

Suitable for low-stress, indoor environments

Provides adequate protection in offices, homes, and commercial spaces

Not designed for extreme conditions or heavy impact

Flexibility and Accessibility

Conduit:

Difficult to modify or expand once installed

Adding cables or making changes requires significant effort, sometimes dismantling sections

Less suited for environments requiring frequent wiring updates

Trunking:

Easy to open and adjust wiring

Simple to add new cables or reroute existing ones

Ideal for spaces needing frequent changes, like offices or school

Which One Should You Choose?

Industrial Settings

Conduit is the clear choice for industrial environments, where safety and durability are paramount. It’s built to handle harsh conditions and protect wiring from physical and environmental threats.

Commercial or Office Spaces

For accessibility and flexibility, trunking is ideal in commercial or office environments. Its easy access allows for frequent updates, making it perfect for areas where wiring needs may evolve over time.

Long-Term vs. Short-Term Needs

When deciding between conduit and trunking, consider the balance between upfront costs and long-term maintenance. Conduit offers durability and low maintenance for long-term use, while trunking provides flexibility and cost savings, especially if frequent wiring changes are anticipated.

Wrapping up

In the end, whether you go with trunking or conduit depends on the project’s environment and future needs. Conduit stands out in tough industrial spaces where durability and safety are key, but it requires more time and money upfront.

On the flip side, trunking offers a budget-friendly, easy-access option that works well in offices and commercial buildings where flexibility and quick updates are important.

So, when choosing between these two cable management systems, think about the long-term demands of your job—whether you need rugged protection or simple adaptability.

What’s the maximum cable capacity for trunking and conduit?

Conduit has strict guidelines on cable fill (typically 40% of its internal diameter) to prevent overheating.

Trunking can hold multiple cables, and its capacity depends on its size. However, overfilling trunking can lead to cable damage and increased difficulty in maintenance, so it’s important to leave some space for future cable additions and to ensure proper ventilation.

Are Wires in Walls Required to Be in Conduit?

Whether or not wires in walls need to be placed in conduit depends on local building codes and regulations. Conduits are often necessary to meet safety standards and ensure electrical installations are up to code, especially in commercial buildings. In many cases, conduits protect the wiring and help prevent hazards, ensuring the installation is both safe and compliant with electrical codes. Always check with your local regulations to see if conduits are required for your specific project.

Do I need special tools for installation?

Conduit installation often requires tools like conduit benders, threading tools (for steel conduit), and cutting devices.

Trunking installation is much simpler, often needing just basic tools like screwdrivers, a saw, and possibly a deburring tool for plastic trunking.

How does conduit handle environmental exposure compared to trunking?

Conduit, particularly metal and PVC types, is designed to handle harsh environmental conditions like extreme temperatures, moisture, and physical impact. Trunking, while effective indoors, is generally less resistant to environmental factors and more suited for controlled indoor environments.