Carltsoe Safety CS Unitec Ex1503D-32A Aluminum Bronze Non-Sparking, Low-Magnetism, Corrosion Resistant Regular Socket 32 mmx 1" Drive x 70 mm Depth (1503DU-32A)

Description

Description

CS Unitec Ex1503D-32A Description

CS Unitec's non-sparking, non-magnetic, corrosion-resistant safety hand tools are manufactured from special Aluminum-Bronze (AlBr) or Copper-Beryllium (CuBe2) alloys. All CS Unitec Safety Tools are backed by a lifetime warranty against defects in workmanship. If any CS Unitec safety tool breaks or fails to perform under normal use or service, it will be repaired or replaced at no charge.* CS Unitec safety tools are high quality manufactured in an ISO 9001:2015 environment and are TUV materials certified. They comply with ATEX Directives for Ex Zones 0, 1 and 2 (Flammable Gas, Mists or Vapors); Zones 20, 21 and 22 (Combustible Dusts); and M1 and M2 for mining. All hand tools are drop forged to produce the highest quality and durability. With over 4,000 SKUs offered, CS Unitec safety tools fit a wide range of applications. Non-Sparking applications include: Ex zones where hazardous, flammable or combustible vapors, liquids, dusts or residues may be present. Non-Magnetic applications include: MRI/NMR, nuclear products, electronic manufacturing, and other sensitive equipment. Corrosion resistant applications include: use in desalination plants, chemical/paper manufacturing, and shipyards. *Any misuse, abuse or normal service wear is not covered under this warranty.

CS Unitec Ex1503D-32A Includes

- (1) Socket Non-Sparking

CS Unitec Ex1503D-32A Features

- Non-Sparking, Non-Magnetic & Corrosion-Resistant Tools for Use in Hazardous Environments, ATEX and EX Zones

- Lifetime Warranty, ISO 9001:2015 manufactured, TUV certified

- Non-Sparking alloys are designed to eliminate the risk of sparks at sites where explosive atmospheres (flammable or combustible vapors, liquids, dusts or residues) may be present

- The non-magnetic feature of these hand tools also makes them ideal for working on MRI, FMRI, NMR, clean room environments and special machinery with powerful magnets. Copper Beryllium recommended for safer non-magnetic applications and around sensistive equipment.

- These corrosion-resistant tools are suitable for use in shipyards, laboratories, pharmaceutical, and food product manufacturing.

- Socket wrenches are made in a wide range of sizes and capacities. All have square drives ranging from 1/4" to 1". Drive size is a measure of capacity. Since Detachable Socket wrenches provide an almost endless combination of handles, attachments and sockets, it is possible to assemble a proper tool for almost any type of service within the tool's capacity.

- Never use a pipe extension or other form of "cheater" to increase the leverage of any wrench. Select a wrench whose opening exactly fits the nut. If possible, always pull on a wrench handle and adjust your stance to prevent a fall if something lets go. There are three types of Sockets hand, power and impact all different in design and hardness. Hand Sockets should never be used on power drive or impact wrenches.

- Not as durable as CuBe

- Low magnetism due to minimal ferrous components. Appropriate for non-critical non-magnetic applications

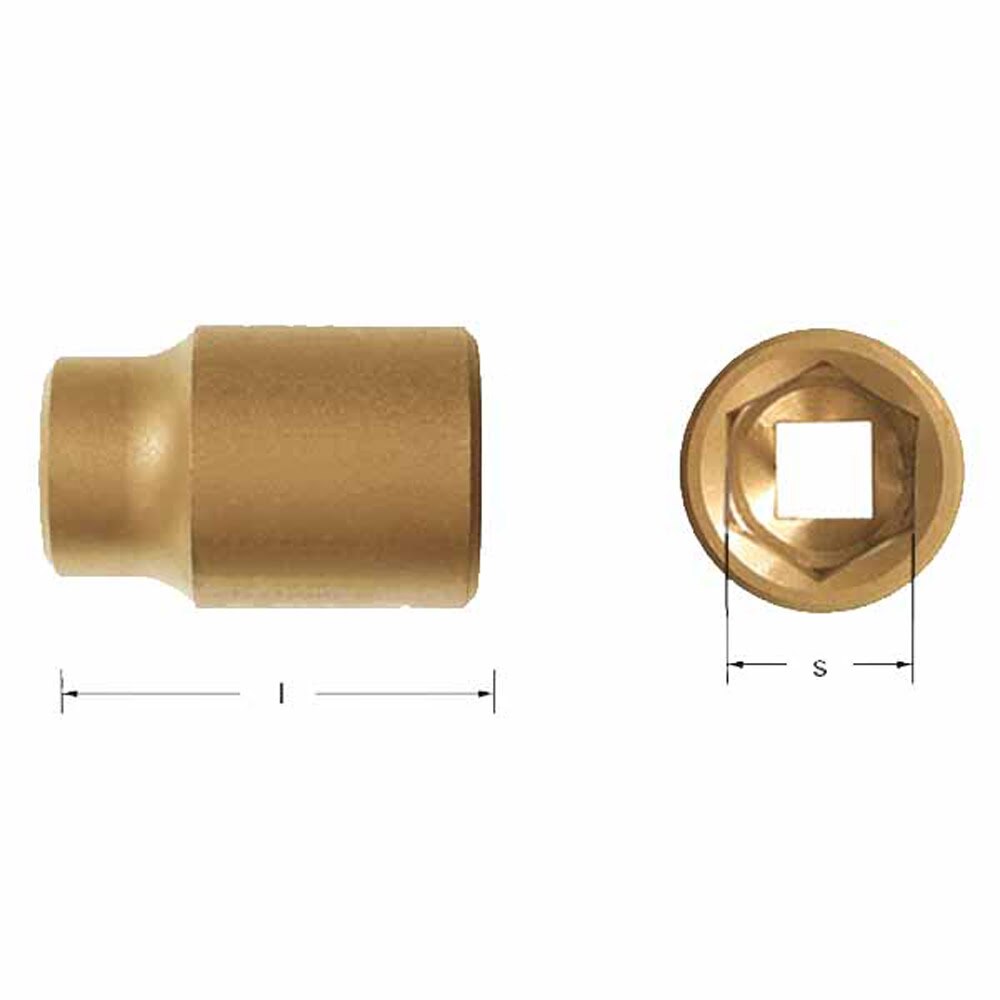

CS Unitec Ex1503D-32A Specifications

| Dimension S | 32 mm |

| Dimension I | 70 mm |

| Dimension A | 1" |

| Alloy | Aluminum-Bronze (AlBr) |

| Zone Compatibility | ATEX Directive 1999/92/EC for work in Zones 0 / 1 / 2 / 20 / 21 / 22 / M1 / M2 |

| Rockwell Hardness | 27 |

| Composition | Al |

| WARNING | This product can expose you to chemicals including Nickel (Ni) that is known to the State of California to cause cancer. For more information go to www.P65Warnings.ca.gov |

| Weight | 0.52 Kg |

WARNING: This product can expose you to chemicals, which are known to the State of California to cause cancer and birth defects or other reproductive harm. www.p65warnings.ca.gov

WARNING: This product can expose you to chemicals, which are known to the State of California to cause cancer and birth defects or other reproductive harm. www.p65warnings.ca.gov

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.